The Unseen Dance: How AI and New Discoveries Are Rewriting Chemical Reactivity

From the spark of iron rusting to the intricate synthesis of life-saving drugs, chemical reactivity is the fundamental process that shapes our material world.

Article Navigation

Today, we stand at a revolutionary crossroads where artificial intelligence and startling new discoveries are revealing that even our most fundamental chemical understandings might be due for a rewrite.

The Fundamentals: Why Molecules React

Chemical Reactivity

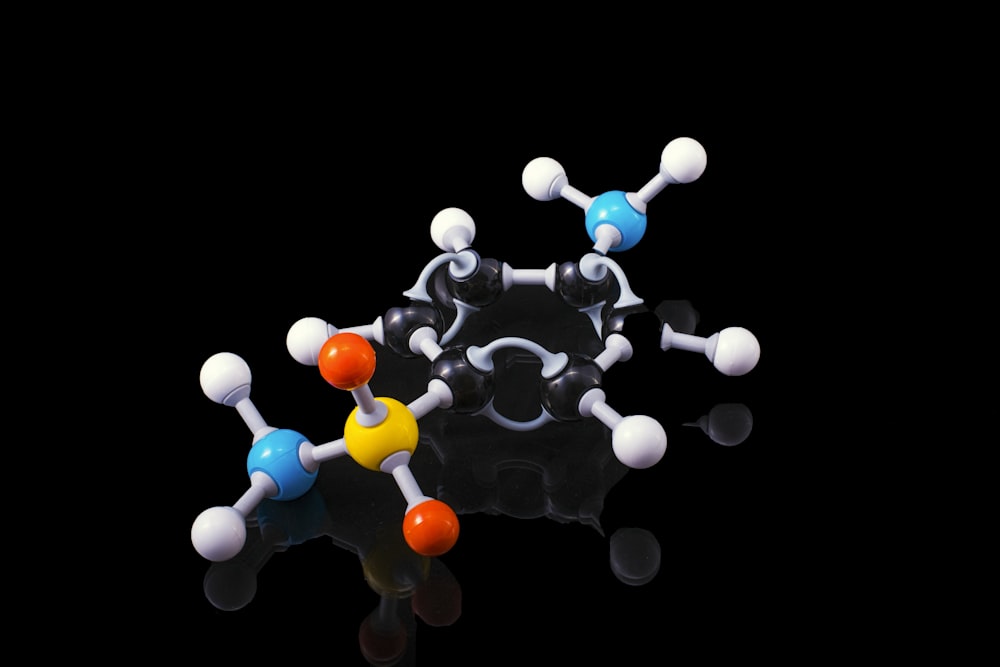

At its heart, chemical reactivity concerns how substances interact to form new products. It's a complex dance governed by electron arrangements and energy states as atoms seek more stable configurations2 .

Molecular Stability

Molecules react because they "want" to be in a state that is more stable, achieved mainly by rearranging electrons amongst orbitals—the cloudlike regions around atomic nuclei where electrons are likely to be located3 .

The "Oxo Wall" Concept

In transition metal chemistry, an important concept known as the "oxo wall" describes why metals toward the end of the transition series struggle to form stable multiple bonds with oxygen or nitrogen atoms2 . This limitation stems from their electronic configurations and significantly impacts their reactivity, especially in catalytic processes.

The AI Revolution: Teaching Computers Chemical Intuition

Predicting how chemicals will react has long been more art than science, relying heavily on a chemist's experience and intuition. Previous attempts to harness artificial intelligence for this task had a significant flaw: they often violated fundamental physical principles like the conservation of mass1 .

FlowER: The Mass-Conserving AI

A team at MIT has developed a groundbreaking approach called FlowER (Flow matching for Electron Redistribution) that maintains real-world physical constraints while predicting reactions1 .

How FlowER Works

Instead of treating atoms as independent tokens like conventional AI models might, FlowER uses a bond-electron matrix—a method originally developed in the 1970s—to represent the electrons in a reaction1 . This system explicitly tracks all electrons throughout the reaction process, ensuring none are spuriously added or deleted.

AI systems like FlowER are revolutionizing how we predict chemical reactions.

Comparison of Reaction Prediction Approaches

| Method | Basis of Operation | Mass Conservation | Key Limitation |

|---|---|---|---|

| Traditional LLMs | Token-based atom representation | Often violated | Can create or delete atoms unrealistically |

| FlowER System | Bond-electron matrix | Explicitly enforced | Limited data on metals and catalytic reactions |

| Human Intuition | Experience and theoretical knowledge | Generally respected | Difficult to scale and quantify |

"That helps us to conserve both atoms and electrons at the same time," explains researcher Mun Hong Fong1 .

Rewriting Textbooks: The Flipped Reaction

The Oxidative Addition Flip

Researchers uncovered a surprising twist in a fundamental chemical reaction known as oxidative addition. This process, where transition metals interact with organic compounds, was typically believed to involve metals donating electrons to organic compounds3 .

The Penn State team discovered an alternate path—one in which electrons instead move from the organic molecule to the metal. This reversal could mean chemists have misunderstood this fundamental step for decades3 .

Laboratory experiments revealed surprising electron movement in oxidative addition reactions.

"It has been noted that some oxidative additions are a little different. A subgroup are actually accelerated by transition metal compounds that are electron deficient. We were able to identify a plausible explanation, where instead of the transition metal donating elections, the first step in the reaction involved electrons moving from an organic molecule to the transition metal"3 .

Inside the Lab: The Hydrogen Experiment That Challenged Convention

Let's take a detailed look at the groundbreaking experiment that revealed this flipped reaction pathway.

Preparation

The team started with compounds containing the transition metals platinum and palladium that were intentionally not electron dense—contrary to conventional wisdom which typically uses electron-rich metals for such reactions3 .

Exposure to Hydrogen

These metal compounds were exposed to hydrogen gas (H₂), the simplest possible molecule for studying bond-breaking processes3 .

Monitoring

Using nuclear magnetic resonance (NMR) spectroscopy, the researchers monitored changes to the transition metal complex in real-time, allowing them to observe intermediate steps that had previously gone undetected3 .

Identification

The instrumentation revealed a crucial intermediate step indicating that hydrogen had donated its electrons to the metal complex prior to approaching the final product state3 .

Experimental Results of Hydrogen-Metal Reactions

| Metal Center | Traditional Mechanism | Newly Observed Mechanism | Final Product Identity |

|---|---|---|---|

| Platinum | Metal → Substrate electron flow | Substrate → Metal electron flow | Identical to traditional product |

| Palladium | Metal → Substrate electron flow | Substrate → Metal electron flow | Identical to traditional product |

Key Finding

The final reaction product was indistinguishable from what would be expected through conventional oxidative addition, but the pathway to get there was completely different. The key evidence was the detection of an intermediate species that could only form if electron transfer had occurred from the organic molecule to the metal3 .

The Scientist's Toolkit: Essential Research Reagents

Modern chemical reactivity research relies on specialized materials and tools. Here are key components from cutting-edge studies:

Transition Metal Complexes

Provide diverse electron arrangements for breaking and forming chemical bonds.

Example: Platinum and palladium compounds in oxidative addition studies3

Bond-Electron Matrix

Computational representation ensuring conservation of mass and electrons.

Example: FlowER system for predicting reaction outcomes1

Deuterated Solvents

Enable NMR spectroscopy without interfering signals.

Example: Monitoring reaction intermediates in the hydrogen study3

Ball Mill Apparatus

Enables solvent-free mechanochemical reactions through grinding.

Example: PTFE upcycling into sodium fluoride4

Sodium Metal

Powerful reducing agent for breaking strong chemical bonds.

Example: Defluorination of PTFE in waste transformation4

Beyond the Lab: Real-World Applications

Understanding and controlling chemical reactivity has profound implications beyond academic interest:

Environmental Solutions

The new understanding of electron transfer in reactions could lead to better methods for breaking down stubborn pollutants3 .

Meanwhile, researchers are developing innovative ways to address persistent waste problems, such as transforming nonstick Teflon coatings into sodium fluoride for toothpaste—a process that uses grinding in a ball mill to create a solvent-free reaction with 100% atom economy4 .

The Future of Chemical Discovery

The combination of physical principle-based AI like FlowER and new mechanistic understandings promises to accelerate the discovery of new reactions and materials1 .

"In the long term, a lot of the excitement is in using this kind of system to help discover new complex reactions and help elucidate new mechanisms. I think that the long-term potential impact is big"1 .

Conclusion: The Evolving Landscape of Chemical Prediction

The field of chemical reactivity is undergoing a remarkable transformation. Artificial intelligence systems that respect fundamental physical laws are beginning to complement human intuition, while surprising discoveries are reminding us that even established textbook reactions may hold hidden secrets.

What was once considered settled science is revealing new layers of complexity, opening exciting possibilities for designing more efficient industrial processes, developing new materials, and addressing environmental challenges. The dance of electrons continues to surprise us, inviting a new generation of chemists to explore its intricate steps and hidden rhythms.

As these developments converge, we're witnessing not just the evolution of chemical understanding, but a revolution in how we approach molecular design itself—with implications that will resonate through medicine, materials science, and environmental technology for decades to come.

The intricate dance of electrons continues to reveal new secrets in chemical reactivity.