Optimized Spectrophotometric Determination of Iron via 1,10-Phenanthroline Complexation: A Comprehensive Guide for Biomedical Research

This article provides a comprehensive review of the spectrophotometric determination of iron using the 1,10-phenanthroline complex, a cornerstone method in analytical chemistry.

Optimized Spectrophotometric Determination of Iron via 1,10-Phenanthroline Complexation: A Comprehensive Guide for Biomedical Research

Abstract

This article provides a comprehensive review of the spectrophotometric determination of iron using the 1,10-phenanthroline complex, a cornerstone method in analytical chemistry. Tailored for researchers and drug development professionals, it covers foundational principles of the ferroin complex and the Beer-Lambert law. The scope extends to detailed, optimized methodologies for diverse sample matrices, including sophisticated techniques for overcoming common interferences like oxalate. We critically address troubleshooting for accuracy and precision and present a rigorous validation framework comparing the method against advanced techniques such as ICP-MS and AAS. This guide serves as a vital resource for reliable iron quantification in pharmaceuticals, biological fluids, and environmental samples, supporting quality control and clinical diagnostics.

The Science Behind the Color: Principles of the 1,10-Phenanthroline-Iron Complex

The ferroin complex, known chemically as tris(1,10-phenanthroline)iron(II), serves as a cornerstone in analytical chemistry for the spectrophotometric determination of iron [1]. Its characteristic intense orange-red coloration provides a sensitive, reliable means to quantify iron concentration across diverse fields—from environmental water testing to pharmaceutical development and materials science [2] [3]. The complex's utility stems from a robust and well-defined binding mechanism between the ferrous ion (Fe²⁺) and the 1,10-phenanthroline ligand, resulting in a chromophore with exceptional stability and distinct spectrophotometric properties. This application note details the binding mechanism, outlines standardized protocols, and presents key analytical parameters to equip researchers with the knowledge to leverage this reaction effectively within a broader research context focused on iron speciation and quantification.

Mechanism of Fe²⁺ Binding and Color Development

The development of the orange-red color is a direct consequence of a specific coordination chemistry event: the formation of a stable, octahedral complex between Fe²⁺ and three molecules of 1,10-phenanthroline.

Chemical Binding Mechanism

The process involves a redox reaction and subsequent chelation. In solution, iron is often present in the more stable Fe³⁺ state. The first critical step is its reduction to the ferrous state (Fe²⁺) by a reducing agent such as hydroxylamine hydrochloride [3]. The reaction proceeds as follows:

- Reduction:

Fe^(3+) + NH2OH -> Fe^(2+) + ...[3] - Chelation: Once reduced, each Fe²⁺ ion coordinates with three 1,10-phenanthroline (phen) molecules:

Fe^(2+) + 3 phen -> [Fe(phen)3]^(2+)[1]

The resulting [Fe(phen)3]²⁺ cation is the ferroin complex. Its structure is octahedral, with D3 symmetry, where each bidentate phenanthroline ligand donates two nitrogen atoms to the iron center, creating a very stable chelate ring system [1]. The iron-nitrogen bond distance in this complex is approximately 197.3 pm [1].

Origin of the Orange-Red Color

The intense color of the ferroin complex is a result of its electronic structure. The 1,10-phenanthroline ligand is a π-acceptor. When it coordinates to the Fe²⁺ ion, molecular orbitals are reconfigured, leading to a narrow energy gap between the highest occupied molecular orbital (HOMO) and the lowest unoccupied molecular orbital (LUMO). This complex absorbs light in the blue-green region of the visible spectrum (around 510 nm), and the transmitted complementary light is perceived as orange-red [2] [3]. The high molar absorptivity of this charge-transfer transition is what makes the method so sensitive for quantification.

Table 1: Key Spectrophotometric Properties of the Ferroin Complex

| Parameter | Value | Experimental Conditions | Source |

|---|---|---|---|

| Absorption Maximum (λ_max) | 510 nm | Aqueous solution | [3] |

| Molar Absorptivity | ~1.3 x 10⁴ L/mol·cm | Not specified | [4] |

| Optimal pH Range | 3 - 9 (4 - 7 ideal) | Acetate buffer | [3] |

| Color Stability | Up to 4 days | Light-proof environment | [4] |

| Detection Limit | 2.5 µg/L (0.0025 ppm) | Portable measurement device | [2] |

| Linear Range | 25 - 1000 µg/L | Portable measurement device | [2] |

| Linear Range | 1 - 9 ppm | Standard UV-Vis | [3] |

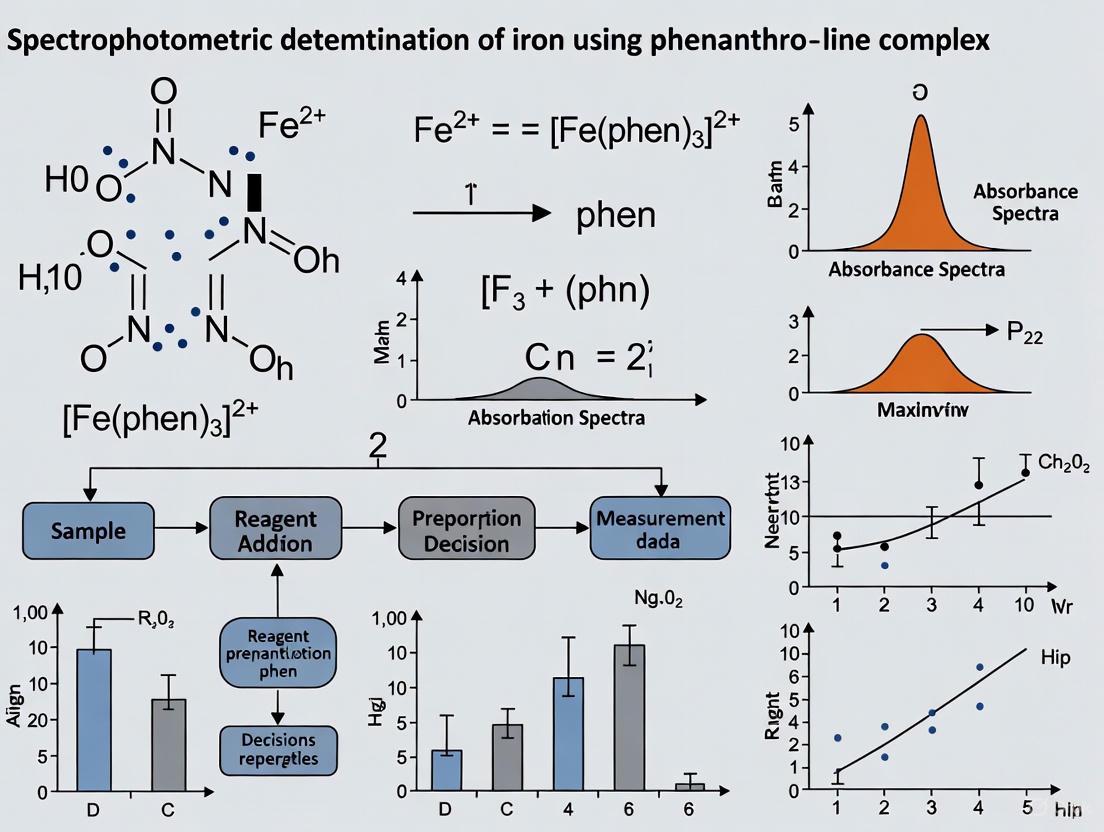

Figure 1: Mechanism of Ferroin Complex Formation. The pathway illustrates the reduction of Fe³⁺ to Fe²⁺ followed by chelation with 1,10-phenanthroline to form the colored complex.

Detailed Experimental Protocols

Standard Protocol for Iron Determination in Aqueous Solution

This protocol is adapted for determining total iron in water samples and requires a UV-Vis spectrophotometer [3].

Materials & Reagents:

- Hydroxylamine hydrochloride solution (10% m/v)

- Sodium acetate buffer (to maintain pH 3-9)

- 1,10-Phenanthroline solution (0.5% m/v)

- Volumetric flasks, pipettes

Procedure:

- Sample Preparation: Transfer a known volume of water sample containing 1-9 ppm of iron into a 100 mL volumetric flask.

- Reduction of Fe³⁺: Add 1 mL of 10% hydroxylamine hydrochloride solution and swirl to mix. This ensures all iron is in the Fe²⁺ state [3].

- pH Buffering: Add 10 mL of sodium acetate buffer to maintain the pH between 4 and 7, which is optimal for complex formation and prevents iron hydrolysis [3].

- Complex Formation: Add 5 mL of 0.5% 1,10-phenanthroline solution and swirl to mix.

- Dilution and Incubation: Dilute to the 100 mL mark with deionized water and allow the solution to stand for 10-15 minutes for full color development.

- Spectrophotometric Measurement: Measure the absorbance of the solution at 510 nm against a reagent blank. Determine the iron concentration from a pre-established calibration curve.

Protocol for Complex Matrices: Overcoming Oxalate Interference

In sequential mineral extraction from sediments, oxalate is a common extractant that interferes by competing with phenanthroline for iron complexation. This protocol addresses that challenge [4].

Procedure:

- Sample Extraction: Obtain an iron-containing sample extracted using an oxalate solution.

- pH Adjustment: To overcome the competitive complexation by oxalate, adjust the pH of the extracted solution to a range of 7–9 using sodium hydroxide (NaOH) or concentrated ammonia [4]. This pH adjustment is critical for successful color development in the presence of oxalate.

- Follow Standard Protocol: Continue with the standard protocol steps (reduction, buffering, complex formation, and measurement) as described in section 3.1. The color stability is maintained for up to 4 days if kept in a light-proof environment [4].

Protocol for Iron Catalyst Content in Carbon Nanotubes (CNTs)

This method is validated for quantifying residual iron catalyst in CNTs using acid digestion to free the encapsulated iron [3].

Procedure:

- Acid Digestion: Reflux approximately 0.1 g of CNTs in a 3:1 (v/v) mixture of H₂SO₄/HNO₃ or HClO₄/HNO₃ to completely extract the iron. The graphitic layers encasing the catalyst particles require strong oxidative acids for dissolution [3].

- Solution Preparation: Cool and filter the digestate. Transfer a known aliquot to a volumetric flask.

- Follow Standard Protocol: Dilute the aliquot as necessary and follow the standard protocol for iron determination (section 3.1). The measured concentration is calculated back to the original CNT mass using the formula:

[Fe] (wt.%) = [Fe]_measured (ppm) × Dilution Factor × Final Volume (L) / m_CNT (g) × 10⁻⁴[3].

Figure 2: Experimental Workflow for Iron Determination. The flowchart outlines the specific steps for different sample types, highlighting the critical pH adjustment for oxalate-containing samples.

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Research Reagent Solutions for Ferroin-based Iron Determination

| Reagent/Material | Function & Role in the Assay | Specifications & Notes |

|---|---|---|

| 1,10-Phenanthroline | Chelating agent: Forms the orange-red [Fe(phen)₃]²⁺ complex. The key chromophore. | ≥99.0% purity (AR Grade). Iron content ≤0.001%. White to pale yellow crystalline powder [5]. |

| Hydroxylamine Hydrochloride (NH₂OH·HCl) | Reducing agent: Converts Fe³⁺ to Fe²⁺, ensuring all iron is in the reactive ferrous state [3]. | Typically used as a 10% (m/v) aqueous solution. |

| Sodium Acetate (CH₃COONa) | Buffering agent: Maintains solution pH in the optimal 4-7 range for stable complex formation [3]. | Prevents hydrolysis of iron and ensures maximum color intensity. |

| Ammonia (NH₃) / Sodium Hydroxide (NaOH) | pH adjustment: Critical for analyzing samples containing interfering complexing agents like oxalate [4]. | Used to raise pH to 7-9 to overcome competition from oxalate. |

| Portable Spectrophotometer | Detection: Measures absorbance of the complex at 510 nm for quantification in field applications [2]. | Can be a custom device with LED (510 nm) and photodiode. Enables sub-ppm detection. |

Applications and Concluding Remarks

The robustness of the ferroin complex reaction facilitates its use in diverse scenarios. It is the basis for standard methods for iron determination in water [2], and with the protocol modifications discussed, it can be applied to environmental monitoring of iron minerals in sediments [4]. The method also extends to materials science, providing a low-cost alternative to ICP-OES for quantifying metal impurities in advanced materials like carbon nanotubes [3].

In conclusion, the binding of Fe²⁺ by 1,10-phenanthroline to form the ferroin complex is a classic, yet highly adaptable, spectrophotometric method. Its mechanism is well-understood, and its protocols can be modified to suit various sample matrices. The provided detailed protocols, key parameters, and workflow are designed to ensure that researchers and drug development professionals can reliably apply this technique to their specific iron quantification needs.

The Beer-Lambert Law (also known as Beer's Law) is a fundamental principle in optical spectroscopy that describes the linear relationship between the absorbance of light and the properties of the material through which the light is traveling [6]. This empirical relationship serves as a critical tool for quantitative chemical analysis, enabling researchers to determine the concentration of solutes in solution by measuring light absorption [7]. In the context of iron quantification, this law provides the theoretical foundation for spectrophotometric determination using complexing agents such as 1,10-phenanthroline, allowing for precise, reproducible measurements essential to pharmaceutical and environmental research [8].

The law mathematically expresses that the attenuation of monochromatic light as it passes through a sample solution is directly proportional to the concentration of the absorbing species and the path length the light travels through the material [9]. The modern formulation of this relationship is represented by the equation:

A = εlc

Where:

- A is the measured absorbance (dimensionless)

- ε is the molar absorptivity or molar extinction coefficient (L·mol⁻¹·cm⁻¹)

- l is the optical path length through the sample (cm)

- c is the concentration of the absorbing species (mol/L) [9] [7]

Theoretical Principles

Fundamental Concepts of Light Absorption

When light passes through a solution containing absorbing species, a portion of the incident light is absorbed, leading to attenuation of the transmitted light beam. The key concepts for understanding this phenomenon include:

- Transmittance (T): Defined as the ratio of the transmitted light intensity (I) to the incident light intensity (I₀), often expressed as a percentage: %T = (I/I₀) × 100% [6]

- Absorbance (A): Defined as the base-10 logarithm of the reciprocal of transmittance: A = log₁₀(I₀/I) [6] [9]

- Molar Absorptivity (ε): A substance-specific constant that indicates how strongly a chemical species absorbs light at a particular wavelength [9]

The following table illustrates the inverse logarithmic relationship between absorbance and transmittance:

Table 1: Absorbance and Transmittance Relationship

| Absorbance | Transmittance |

|---|---|

| 0 | 100% |

| 0.3 | 50% |

| 1 | 10% |

| 2 | 1% |

| 3 | 0.1% |

Data adapted from Edinst resource on Beer-Lambert Law [6]

Mathematical Formulations and Limitations

The Beer-Lambert law derives from differential calculus, assuming that the decrease in light intensity (dI) through an infinitesimally thin layer of solution is proportional to the incident intensity (I), the concentration of the absorber (c), and the thickness of the layer (dx). This leads to the exponential attenuation relationship formally expressed as:

I = I₀e^(-μl) or in logarithmic form: A = log₁₀(I₀/I) = εlc [10]

Despite its widespread utility, the Beer-Lambert law has several important limitations that researchers must consider:

- Concentration Limitations: At high concentrations (>0.01M), the linear relationship between absorbance and concentration may deviate due to molecular interactions, electrostatic effects, or changes in refractive index [7] [11]

- Chemical Deviations: Apparent non-linearity can occur due to association, dissociation, or complexation equilibria of the absorbing species [11]

- Instrumental Deviations: Stray light, polychromatic radiation, and detector non-linearity can cause measurement inaccuracies, particularly at high absorbance values [7] [11]

- Optical Effects: Scattering, fluorescence, or optical saturation can invalidate the fundamental assumptions of the law [11]

The following diagram illustrates the fundamental relationship between light attenuation and solution properties described by the Beer-Lambert Law:

Spectrophotometric Determination of Iron

Iron-Phenanthroline Complex Formation

The spectrophotometric determination of iron using 1,10-phenanthroline represents a classic application of the Beer-Lambert Law in analytical chemistry. This method relies on the formation of a stable, intensely colored complex between ferrous iron (Fe²⁺) and 1,10-phenanthroline, producing the tris(1,10-phenanthroline)iron(II) cation, commonly known as ferroin [8].

The complex formation reaction proceeds as follows:

Fe²⁺ + 3C₁₂H₈N₂ → [Fe(C₁₂H₈N₂)₃]²⁺

This complex exhibits a characteristic red-orange color with maximum absorption at 510 nm [8]. The high molar absorptivity of the complex (approximately 11,000 L·mol⁻¹·cm⁻¹) enables sensitive detection of iron at trace concentrations, with Beer's law typically obeyed over the concentration range of 1.1-11.2 μg of iron in 10 ml of eluate [8].

The formation constant of the iron(III)-1,10-phenanthroline complex has been determined in methanol solution, with stability influenced by the solvent medium. The complex demonstrates sufficient stability for accurate quantification while maintaining reproducibility across analytical replicates [12].

Research Reagent Solutions and Materials

Table 2: Essential Research Reagents for Iron-Phenanthroline Complex Method

| Reagent/Material | Function/Specification |

|---|---|

| 1,10-Phenanthroline | Complexing agent that forms colored complex with Fe²⁺ |

| Hydroxylamine hydrochloride | Reducing agent to convert Fe³⁺ to Fe²⁺ |

| Sodium acetate | pH buffer to maintain optimal conditions (pH 3-9) |

| Iron standard solution | Primary standard for calibration curve |

| Chitin (natural polymer) | Solid phase for preconcentration in column methods |

| Acetone-acetic acid eluent | Elution mixture (8:2 v/v) for recovery of complex |

| Cuvettes | Optical cells with standard 1 cm path length |

Information compiled from published methodologies [8] [12]

Experimental Protocols

Calibration Curve Methodology

The quantification of iron via spectrophotometry requires the establishment of a calibration curve using standard solutions of known concentration. The general procedure involves the following steps:

- Preparation of Standard Solutions: Create a series of iron standard solutions covering the concentration range of interest (typically 0.5-5.0 ppm)

- Complex Development:

- Add 1 mL of hydroxylamine hydrochloride solution (10% w/v) to each standard to reduce Fe³⁺ to Fe²⁺

- Add 2 mL of 1,10-phenanthroline solution (0.1% w/v in ethanol)

- Add 5 mL of sodium acetate solution (10% w/v) to buffer at pH ~3.5

- Dilute to volume with deionized water and allow 15 minutes for color development

- Absorbance Measurement: Measure absorbance at 510 nm against a reagent blank

- Calibration Plot: Graph absorbance versus concentration and determine the best-fit line

Table 3: Typical Calibration Data for Iron-Phenanthroline Complex

| Iron Concentration (μg/10 mL) | Absorbance at 510 nm |

|---|---|

| 0.0 | 0.000 |

| 2.0 | 0.180 |

| 4.0 | 0.360 |

| 6.0 | 0.540 |

| 8.0 | 0.720 |

| 10.0 | 0.900 |

Hypothetical data based on typical molar absorptivity of ~11,000 L·mol⁻¹·cm⁻¹

Sample Preparation and Analysis Workflow

The following diagram outlines the complete experimental workflow for the spectrophotometric determination of iron using the phenanthroline complex method:

For water samples or complex matrices, a preconcentration step may be incorporated using chitin as a natural polymer substrate. The iron-phenanthroline complex is retained on a chitin column in the presence of tetraphenylborate as a counter-ion, then eluted with an acetone-1M acetic acid mixture (8:2 v/v) prior to absorbance measurement [8].

Interference Studies

The iron-phenanthroline method exhibits good specificity when proper masking agents are employed. EDTA (ethylenediaminetetraacetic acid) effectively masks common interferents:

- No interference from Ca, Mg, Al, Mn, Zn, Cd, and Pb at concentrations up to 100 times that of iron

- No interference from Co, Ni, and Cu at concentrations up to 20 times that of iron

- Common inorganic anions show no interference at concentrations up to 10,000 times that of iron [8]

This selectivity profile makes the method particularly suitable for analyzing iron in complex matrices such as environmental waters, biological samples, and pharmaceutical formulations.

Applications in Research and Development

The spectrophotometric determination of iron using the Beer-Lambert Law has extensive applications across multiple scientific disciplines:

- Environmental Monitoring: Determination of iron in tap water, groundwater, and wastewater at concentration ranges of 1.1-11.2 μg/10 mL [8]

- Pharmaceutical Analysis: Quality control of iron-containing pharmaceuticals and nutritional supplements

- Biological Research: Quantification of iron in biological fluids and tissues for metabolic studies

- Materials Science: Analysis of iron complexes for applications in dye-sensitized solar cells as sustainable alternatives to ruthenium-based dyes [12]

- Industrial Processes: Monitoring iron concentrations in manufacturing processes and quality assurance protocols

The iron-phenanthroline method offers advantages of sensitivity, selectivity, and cost-effectiveness compared to more sophisticated techniques like atomic absorption spectroscopy or ICP-MS, while maintaining sufficient accuracy for routine analytical applications.

Data Analysis and Validation

Calculation of Iron Concentration

For samples falling within the linear range of the calibration curve, the iron concentration is determined directly from the linear regression equation:

c = (A - b) / m

Where:

- c = iron concentration

- A = measured absorbance

- b = y-intercept of calibration curve

- m = slope of calibration curve

The molar absorptivity (ε) can be calculated from the slope of the calibration curve using the relationship:

ε = m × (l)⁻¹

Where l is the path length in cm (typically 1 cm).

Method Validation Parameters

To ensure reliable results, method validation should include assessment of:

- Linearity: Correlation coefficient (r²) typically >0.995 across the working range

- Limit of Detection (LOD): Approximately 0.1 μg/10 mL for preconcentration methods

- Limit of Quantification (LOQ): Approximately 0.3 μg/10 mL

- Precision: Relative standard deviation <5% for replicate analyses

- Accuracy: Determination via spike recovery studies (95-105% recovery)

The robust theoretical foundation provided by the Beer-Lambert Law, combined with the well-characterized iron-phenanthroline complex chemistry, makes this methodology particularly valuable for research applications requiring precise iron quantification across diverse sample matrices.

The spectrophotometric determination of iron using 1,10-phenanthroline is a fundamental method in analytical chemistry for assessing drinking water quality. The reliability of this analysis is heavily dependent on two critical reagent systems: hydroxylamine hydrochloride as a reducing agent and pH buffers to maintain the optimal analytical environment. This application note details their specific roles, protocols for use, and key considerations to ensure accurate and reproducible results. The method is based on the formation of a red-orange tris(1,10-phenanthroline)iron(II) complex, a chelate known for its high molar absorptivity and stability, which allows for the sensitive detection of trace iron levels in water samples [13] [14].

The Scientist's Toolkit: Essential Reagents and Their Functions

The successful determination of iron via this spectrophotometric method requires a specific set of reagent solutions. The table below catalogs these essential materials and explains their critical function within the analytical protocol.

Table 1: Key Research Reagent Solutions for the Spectrophotometric Determination of Iron

| Reagent Solution | Function in the Analysis |

|---|---|

| 1,10-Phenanthroline | A chelating agent that selectively reacts with Fe²⁺ ions to form the intensely colored Fe(phen)₃²⁺ complex, which is measured spectrophotometrically [13] [14]. |

| Hydroxylamine Hydrochloride | A critical reducing agent that converts any Fe³⁺ ions present in the sample to Fe²⁺, ensuring that the total dissolved iron is available for complexation [13]. It also maintains iron in the +2 state by counteracting re-oxidation by dissolved oxygen [13]. |

| Sodium Acetate Buffer | Maintains the reaction pH within the optimal range (pH 3 to 3.5). This ensures rapid and complete complex formation, prevents oxidation of Fe²⁺, and stops H⁺ ions from competing for the phenanthroline reagent [13] [14]. |

| Standard Iron Solution | A solution of known iron concentration, typically prepared from Fe(NH₄)₂(SO₄)₂•6H₂O (ferrous ammonium sulfate), used to construct the calibration curve for quantitative analysis [13]. |

| Sulfuric Acid (H₂SO₄) | Used in the preparation of the standard iron stock solution to prevent hydrolysis and precipitation of the iron salt, ensuring its stability [13]. |

Roles and Mechanisms of Critical Reagents

Hydroxylamine Hydrochloride: The Reducing Agent

Hydroxylamine hydrochloride (NH₂OH•HCl) serves a dual purpose in the analytical procedure. Its primary function is the quantitative reduction of Fe³⁺ to Fe²⁺. Since iron in aerated water is predominantly found in the +3 oxidation state, this reduction is essential for the method to measure total dissolved iron [13]. The reaction can be summarized as: 2Fe³⁺ + 2NH₂OH•HCl → 2Fe²⁺ + N₂↑ + 2H₂O + 4H⁺ + 2Cl⁻

Secondly, an excess of hydroxylamine is required to maintain the iron in its reduced state throughout the analysis. Dissolved oxygen in the solution can slowly reoxidize Fe²⁺ back to Fe³⁺ over time. The presence of the reducing agent acts as a sacrificial agent, preventing this reoxidation and thereby stabilizing the developed color and ensuring the analytical signal remains stable [13].

Sodium Acetate: The pH Buffer

The function of the sodium acetate buffer is to provide a stable and optimal pH environment, which is critical for the quantitative and reproducible formation of the iron-phenanthroline complex. The recommended pH range for the analysis is between 3.2 and 3.5 [13] [14]. The buffer's role is threefold:

- Ensures Complete Complexation: Within this pH window, the complexation of Fe²⁺ by three phenanthroline molecules proceeds rapidly and to completion.

- Prevents Iron Oxidation: At a pH that is too high (e.g., >9), the ferrous ion (Fe²⁺) is susceptible to oxidation to ferric ion (Fe³⁺), which does not form the colored complex with phenanthroline [13].

- Suppresses Reagent Protonation: At a pH that is too low (e.g., <3), the high concentration of H⁺ ions competes with Fe²⁺ for the basic nitrogen sites on the 1,10-phenanthroline molecule, leading to the formation of phenanthroline hydrochloride (phenH⁺) and resulting in incomplete complexation [13].

Experimental Protocols

Preparation of Reagent Solutions

The following solutions should be prepared for the analysis [13]:

- Hydroxylamine hydrochloride (0.29 M): Dissolve an appropriate mass of NH₂OH•HCl in deionized water.

- 1,10-Phenanthroline (5.0 x 10⁻³ M): Dissolve the chelating agent in deionized water.

- Sodium acetate buffer (1.2 M): Prepare a solution of sodium acetate in deionized water. The pH will naturally be in the required range.

- Standard iron stock solution (5.0 x 10⁻⁴ M): Accurately weigh about 0.100 g of ferrous ammonium sulfate hexahydrate (Fe(NH₄)₂(SO₄)₂•6H₂O, FW = 392.14). Transfer it quantitatively to a 500 mL volumetric flask. Add about 10 mL of 2 M H₂SO₄ and 50 mL of deionized water to dissolve the salt. Dilute to the mark with deionized water and mix thoroughly.

Sample and Calibration Standard Preparation

This procedure outlines the preparation of both calibration standards and unknown water samples for spectrophotometric measurement [13].

Figure 1: Sample and standard preparation workflow for the phenanthroline-based iron determination method.

- Prepare Working Standards: Pipet 0, 0.5, 1.0, 1.5, 2.0, and 2.5 mL of the standard iron stock solution into a series of six labeled 50 mL volumetric flasks. The '0' mL standard serves as the method blank.

- Prepare Water Samples: Pipet a 25 mL aliquot of the water sample (e.g., cold or hot tap water) into a separate 50 mL volumetric flask. If the iron concentration is expected to be high, a smaller volume should be used and diluted to the mark.

- Add Reagents Sequentially: To each flask, add the following reagents in order:

- 1.0 mL of 0.29 M hydroxylamine hydrochloride solution.

- 5.0 mL of 1.2 M sodium acetate solution.

- 5.0 mL of 5.0 x 10⁻³ M 1,10-phenanthroline solution.

- Dilute and Develop Color: Dilute each flask to the 50 mL mark with deionized water and mix thoroughly. Allow the solutions to stand for 10 minutes to ensure complete color development and complex formation. Mix the solutions again before measurement.

Spectrophotometric Measurement and Data Analysis

- Instrument Blanking: Use deionized water as a blank to zero the spectrophotometer. This corrects for any absorbance from the cuvette or the solvent.

- Measure Absorbance: Set the spectrophotometer to a wavelength of 508 nm. Rinse the cuvette with the solution to be measured three times, then fill it and measure the absorbance. It is good practice to work from the lowest to the highest concentration standard to minimize carryover [13].

- Construct Calibration Curve: Plot the average absorbance of the standard solutions against their iron concentration. The concentration of the working standards can be calculated, considering the dilution factor, and is typically expressed in mg/L (ppm). The table below provides an example calculation for the standard series.

Table 2: Preparation and Expected Data for Iron Calibration Standards

| Volume of Standard (mL) | Final [Fe] (mol/L) | Final [Fe] (ppm)* | Expected Absorbance (Example) |

|---|---|---|---|

| 0.0 | 0.00 x 10⁻⁵ | 0.00 | 0.000 |

| 0.5 | 0.50 x 10⁻⁵ | 0.28 | 0.105 |

| 1.0 | 1.00 x 10⁻⁵ | 0.56 | 0.210 |

| 1.5 | 1.50 x 10⁻⁵ | 0.84 | 0.315 |

| 2.0 | 2.00 x 10⁻⁵ | 1.12 | 0.420 |

| 2.5 | 2.50 x 10⁻⁵ | 1.40 | 0.525 |

*Calculated based on a 5.0x10⁻⁴ M stock diluted to 50 mL.

- Data Analysis: Perform linear regression on the standard data to obtain the Beer's Law equation in the form A = m[Fe] + b, where A is absorbance and [Fe] is the iron concentration. The molar absorptivity (ε) of the Fe(phen)₃²⁺ complex can be calculated from the slope (m) and the pathlength of the cuvette (usually 1 cm), using the relationship A = εbc. The literature value for ε is approximately 11,100 M⁻¹cm⁻¹ at 508 nm [13]. Use the calibration equation to determine the concentration of iron in the unknown water samples.

Troubleshooting and Quality Control

- Interferences: Strong oxidizing agents, cyanide, nitrite, phosphates, and high concentrations of certain metal ions like cobalt, copper, and nickel can interfere with the analysis [14]. The initial addition of acid and the excess hydroxylamine help mitigate some of these interferences.

- Quality Control: Analyze a challenge sample of known concentration ("spiked unknown") with each batch to verify method recovery and accuracy [13]. The recovery should ideally be between 95-105%.

- Non-zero intercept: A small non-zero intercept in the calibration curve is common and may be due to background matrix effects. The limit of detection (LOD) and limit of quantitation (LOQ) should be calculated based on the standard error of the calibration curve [13]. The phenanthroline method can achieve a detection limit for iron as low as 10 μg/L with a 5 cm pathlength cell [14].

Within the framework of research on the spectrophotometric determination of iron, identifying the optimal analytical wavelength is a fundamental step for achieving high sensitivity and accuracy. This protocol details the methodology for identifying the maximum absorption wavelength (λmax) of the iron(II)-1,10-phenanthroline complex, a critical parameter for quantitative analysis. The iron-phenanthroline complex exhibits an intense orange-red color, and its absorption maximum is consistently reported in the region of 508 nm to 510 nm [13] [15]. Establishing this λmax allows researchers to leverage the Beer-Lambert Law, which states a linear relationship between absorbance and concentration, thereby enabling the precise determination of iron concentration in unknown samples [6]. This document provides detailed application notes and standardized protocols for this essential analytical procedure.

Theoretical Foundations

The Beer-Lambert Law and Absorbance

The Beer-Lambert Law forms the cornerstone of quantitative absorption spectroscopy. It defines the logarithmic relationship between the attenuation of light through a substance and its properties. The law is mathematically expressed as:

A = ε * c * l

Where:

- A is the Absorbance (a dimensionless quantity) [6].

- ε is the molar absorption coefficient (M⁻¹cm⁻¹), a substance-specific property that measures its absorption strength at a given wavelength [6].

- c is the concentration of the absorbing species (M) [6].

- l is the optical path length (cm), typically the width of the cuvette used for measurement [6].

Absorbance (A) is quantitatively related to transmittance (T), which is the ratio of transmitted (I) to incident light (I₀). The relationship is defined as A = -log(T) [6]. This logarithmic dependence means that small changes in concentration result in measurable changes in absorbance, making it a robust quantitative tool. Key absorbance and transmittance pairings are summarized in Table 1.

Table 1: Fundamental Relationship Between Absorbance and Transmittance

| Absorbance (A) | Transmittance (T) |

|---|---|

| 0 | 100% |

| 1 | 10% |

| 2 | 1% |

| 3 | 0.1% |

| 4 | 0.01% |

| 5 | 0.001% |

The Iron(II)-1,10-Phenanthroline Complex

The determination of iron is based on its reaction with 1,10-phenanthroline (phen) to form a stable, intensely colored complex in solution:

Fe²⁺ + 3 phen → Fe(phen)₃²⁺

This complex, tris(1,10-phenanthroline)iron(II), is responsible for the distinct red-orange color and exhibits a strong absorption band in the visible region due to its molecular structure [13]. Since iron in environmental and biological samples often exists in the +3 oxidation state (Fe³⁺), a quantitative reduction to Fe²⁺ is a critical prerequisite. This is typically achieved using a reducing agent like hydroxylamine hydrochloride [13]. The complexation reaction is also pH-dependent; an appropriate pH range (3 to 9) is maintained using a sodium acetate buffer to ensure complete complex formation and prevent the oxidation of Fe²⁺ or protonation of the reagent [13].

The Scientist's Toolkit: Essential Research Reagents and Materials

The following table lists the key reagents, materials, and instruments required for the spectrophotometric determination of iron via the phenanthroline method.

Table 2: Essential Research Reagent Solutions and Materials

| Item | Function / Role in the Experiment |

|---|---|

| 1,10-Phenanthroline | The complexing agent that reacts with Fe²⁺ to form the colored Fe(phen)₃²⁺ complex [13]. |

| Hydroxylamine Hydrochloride | A reducing agent that converts all iron in the sample to the Fe²⁺ state, ensuring it is available for complexation [13]. |

| Sodium Acetate | A buffer used to maintain the reaction solution at an optimal pH (around 3.5) for complete and stable complex formation [13]. |

| Standard Iron Solution | A solution of known iron concentration (e.g., from Fe(NH₄)₂(SO₄)₂·6H₂O) used to construct the calibration curve [13]. |

| Spectrophotometer | Instrument used to measure the absorbance of light by the solution at specific wavelengths [13] [15]. |

| Cuvette | A container, typically with a 1 cm path length, that holds the sample solution during absorbance measurement [6] [13]. |

| Volumetric Flasks | For accurate preparation and dilution of standard and sample solutions [13]. |

Experimental Protocol

The following diagram outlines the complete experimental workflow for determining iron concentration, from sample preparation to data analysis.

Detailed Procedure for Identifying λmax and Quantifying Iron

A. Preparation of Working Standard Solutions [13]

- Pipet a series of known volumes (e.g., 0, 0.5, 1.0, 1.5, 2.0, and 2.5 mL) of a standard iron solution (e.g., 5.0 x 10⁻⁴ M) into a set of 50 mL volumetric flasks.

- To each flask, add the following reagents in sequence:

- 1 mL of hydroxylamine hydrochloride solution (0.29 M).

- 5 mL of sodium acetate solution (1.2 M).

- 5 mL of 1,10-phenanthroline solution (5.0 x 10⁻³ M).

- Dilute each flask to the 50 mL mark with deionized water and mix thoroughly.

- Allow the solutions to stand for at least 10 minutes to ensure full color development before measuring absorbance.

B. Spectrophotometric Measurement and λmax Identification

- Instrument Blank: Fill a cuvette with deionized water and use it to zero (blank) the spectrophotometer.

- Wavelength Scan: Using the intermediate concentration standard (e.g., 1.5 mL standard solution), measure its absorbance across a range of wavelengths, for example, from 450 nm to 550 nm.

- Identify λmax: Plot absorbance versus wavelength. The peak of this graph is the maximum absorption wavelength (λmax). For the Fe(phen)₃²⁺ complex, this is expected to be between 508 nm and 510 nm [13] [15]. An example of absorption spectra for a different but analogous system is shown in Figure 1.

Table 3: Example Absorbance Data from a Wavelength Scan

| Wavelength (nm) | Absorbance (A) |

|---|---|

| 450 | 0.105 |

| 470 | 0.230 |

| 490 | 0.598 |

| 500 | 0.745 |

| 505 | 0.805 |

| 508 | 0.811 |

| 510 | 0.808 |

| 512 | 0.800 |

| 515 | 0.760 |

| 530 | 0.450 |

| 550 | 0.150 |

C. Quantification of Iron via Calibration Curve

- Measure Standards: Using the λmax identified (e.g., 510 nm), measure the absorbance of all standard solutions prepared in Section A.

- Construct Calibration Curve: Plot the average absorbance of each standard solution against its known iron concentration. Perform linear regression to obtain the calibration equation in the form A = m[Fe] + b, where 'm' is the slope and 'b' is the y-intercept [13] [15].

- Analyze Unknowns: Prepare unknown samples (e.g., groundwater, tap water) following the same procedure as the standards. Measure their absorbance at λmax and use the calibration equation to calculate their iron concentration.

Data Analysis and Reporting

Calibration and Quantitative Results

Accurate reporting of experimental data is crucial for verification and reproducibility [16]. The quantitative data derived from the calibration curve should be clearly summarized. Table 4 provides a template for presenting calibration data, and Table 5 shows an example calculation for an unknown sample.

Table 4: Calibration Data for Iron Determination at 510 nm

| Standard Solution | Iron Concentration (mg/L) | Absorbance (A) | Linear Regression Fit (A) |

|---|---|---|---|

| Blank | 0.00 | 0.000 | 0.005 |

| Std 1 | 0.10 | 0.215 | 0.214 |

| Std 2 | 0.20 | 0.422 | 0.423 |

| Std 3 | 0.30 | 0.641 | 0.632 |

| Std 4 | 0.40 | 0.840 | 0.841 |

| Std 5 | 0.50 | 1.050 | 1.050 |

Calibration Equation: A = 2.083[Fe] + 0.005 | R² = 0.9998

Table 5: Determination of Iron in Unknown Water Samples

| Sample Description | Absorbance (A) | Calculated [Fe] (mg/L) | Compliance with Standard (e.g., ≤0.3 mg/L) |

|---|---|---|---|

| Cold Tap Water | 0.320 | 0.151 mg/L | Compliant |

| Hot Tap Water | 0.405 | 0.192 mg/L | Compliant |

| Groundwater Sample A | 0.680 | 0.324 mg/L | Exceeds Limit |

Calculation of Molar Absorptivity

The molar absorptivity (ε) is a key parameter representing the sensitivity of the method. It can be calculated from the slope (m) of the calibration curve and the path length (l) of the cuvette (typically 1 cm) using the following relationship derived from the Beer-Lambert Law:

ε = m / l

For example, with a slope of 2.083 M⁻¹ and a 1 cm path length, the molar absorptivity would be approximately 2,083 M⁻¹cm⁻¹. This value should be compared with literature values, such as the reported 11,100 M⁻¹cm⁻¹ for Fe(phen)₃²⁺ at 508 nm, with any differences explained by potential methodological variations [13].

Applications and Context in Research

This methodology is directly applicable in environmental monitoring and public health research. For instance, it has been employed to assess iron concentrations in groundwater, with studies confirming that most samples comply with the WHO and Libyan national standard of 0.3 mg/L, though some exceedances necessitate continuous monitoring [15]. The precision of the method is often verified using the standard addition technique, yielding linear equations with high correlation coefficients (e.g., r² = 0.9992), which confirms the reliability of the results and the absence of significant matrix interference [15]. The fundamental principles of absorbance measurement and the utility of λmax extend beyond this specific assay, forming the basis for the analysis of various compounds, including synthetic food dyes like Allura Red AC and Ponceau 4R, where shifts in λmax can be used to study acid-base properties and determine dissociation constants [17].

From Theory to Practice: Step-by-Step Protocols for Complex Matrices

This document outlines a standard operating procedure (SOP) for the spectrophotometric determination of iron via the formation of the red-orange tris(1,10-phenanthroline)iron(II) complex, commonly known as the phenanthroline method. This SOP is framed within ongoing thesis research aimed at refining analytical techniques for transition metal quantification, with applications in pharmaceutical development and environmental science [14] [13]. The method is based on the complexation of ferrous iron (Fe²⁺) with three 1,10-phenanthroline molecules to form a stable, colored complex suitable for quantitative analysis [14].

Principle of the Method

Iron present in a sample is first brought into solution and reduced from the ferric (Fe³⁺) to the ferrous (Fe²⁺) state using hydroxylamine hydrochloride [13] [18]. The ferrous iron then reacts with 1,10-phenanthroline at a controlled pH of 3.2 to 3.5 to form the tris(1,10-phenanthroline)iron(II) complex, which exhibits an intense orange-red color [14]. The absorbance of this complex is measured at 508 nm and is proportional to the iron concentration in the sample, adhering to the Beer-Lambert law [13] [18]. The method is effective for determining both dissolved and total iron, with a typical analytical range of 10 to 500 µg/L [14].

Research Reagent Solutions and Materials

Table 1: Essential Reagents and Materials for the Phenanthroline Method.

| Reagent/Material | Typical Composition/Specification | Function in the Procedure |

|---|---|---|

| 1,10-Phenanthroline | 5.0 x 10⁻³ M aqueous solution [13] | Chromogenic reagent; chelates Fe²⁺ to form the colored complex [14] [18]. |

| Hydroxylamine Hydrochloride | 0.29 M aqueous solution [13] | Reducing agent; converts Fe³⁺ to Fe²⁺ and prevents oxidation by dissolved oxygen [13] [18]. |

| Sodium Acetate Buffer | 1.2 M aqueous solution [13] | pH control; maintains the reaction pH between 3.2 and 3.5 for rapid and complete color development [14] [13]. |

| Sulfuric Acid | 2.0 M [13] or 1.0 M HCl [18] | Sample digestion; used to dissolve and bring iron into solution from solid samples [18]. |

| Standard Iron Solution | e.g., 5.0 x 10⁻⁴ M from Fe(NH₄)₂(SO₄)₂·6H₂O [13] | Calibration; used to prepare a series of standard solutions for constructing the calibration curve. |

| Deionized Water | -- | Solvent and diluent. |

Apparatus and Instrumentation

- Spectrophotometer or Photometer: Capable of measuring absorbance at a wavelength of 508 nm [13] [18].

- Cuvettes: 1 cm light path, or longer paths (e.g., 5 cm) for enhanced sensitivity with low iron concentrations [14].

- Volumetric Flasks: Various sizes (e.g., 50 mL, 500 mL, 1 L) for precise dilution [13] [18].

- Pipettes: Various capacities for accurate transfer of solutions.

- Beakers, Filtration Apparatus (for solid samples) [18].

Experimental Protocol

Sample Preparation

5.1.1 Water Samples: For the determination of total iron, collect a representative sample in a clean, acid-washed container. If necessary, acidify at the time of collection to prevent adsorption of iron to the container walls [14]. For dissolved iron, filter the sample through a 0.45 µm membrane filter immediately after collection [14].

5.1.2 Solid Samples (e.g., Pharmaceuticals, Biological Materials): Accurately weigh a representative portion of the homogenized solid (e.g., a crushed multivitamin pill) [18]. Transfer quantitatively to a beaker, add ~150 mL of 1.0 M HCl, and heat near boiling for 10 minutes to digest and dissolve the iron [18]. Cool, then vacuum-filter the solution to remove particulates. Transfer the clear filtrate to a 1 L volumetric flask and dilute to the mark with deionized water [18].

Reduction and Complex Development

The following procedure is adapted for preparing a 50 mL final volume, suitable for analysis in a cuvette [13].

- Pipette an appropriate aliquot of the sample (e.g., 25 mL for water samples) or standard solution into a 50 mL volumetric flask [13].

- Add 1 mL of hydroxylamine hydrochloride solution and mix [13] [18].

- Add 5 mL of sodium acetate buffer solution and mix. This establishes the optimal pH of 3.2-3.5 [13].

- Add 5 mL of 1,10-phenanthroline solution and mix [13] [18].

- Dilute to the 50 mL mark with deionized water and mix thoroughly.

- Allow the solution to stand for at least 10 minutes to ensure full color development [13].

Spectrophotometric Measurement

- Instrument Setup: Turn on the spectrophotometer and allow it to warm up. Set the wavelength to 508 nm [13] [18].

- Blank Preparation: Prepare a reagent blank using deionized water treated with the same reagents (steps 2-6 above).

- Calibration: Measure the absorbance of the standard solutions. Use the blank to zero the instrument.

- Sample Measurement: Measure the absorbance of the prepared sample solutions.

Data Analysis

- Calibration Curve: Plot the absorbance of the standard solutions against their known iron concentrations. Perform linear regression to obtain the equation of the line (A = m[Fe] + b) [13].

- Concentration Calculation: Use the calibration equation to calculate the concentration of iron in the sample solution based on its measured absorbance.

- Result Calculation: Account for all dilution factors to back-calculate the original iron concentration in the sample [18].

Workflow Visualization

Quality Assurance and Control

- Calibration Verification: Analyze a standard solution as a quality control check with each batch of samples.

- Reagent Blank: A reagent blank must be carried through the entire procedure to correct for any absorbance from impurities [14].

- Precision: Analyze samples in duplicate or triplicate.

- Holding Times: Samples should be analyzed within the specified holding time (e.g., 6 months for properly preserved water samples) [14].

Method Performance and Interferences

Table 2: Analytical Performance and Interfering Substances.

| Parameter | Specification | Notes |

|---|---|---|

| Detection Level | 10 µg/L [14] | With a 5 cm light path. |

| Applicable Range | Up to 500 µg/L and higher [14] | Can be extended by dilution or using a shorter path length. |

| Precision (RSD) | 25.5% [14] | At 300 µg/L level. |

| Color Stability | At least 6 months [14] | For prepared color standards. |

| Common Interferences | Strong oxidizing agents, cyanide, nitrite, phosphates (especially polyphosphates), and high concentrations of Co, Cu, Ni, Zn, Cd, Hg, Ag, Bi [14]. | Initial boiling with acid converts polyphosphates and removes cyanide/nitrite. Excess hydroxylamine counters oxidizers. Excess phenanthroline can mitigate metal ion interference [14]. |

The spectrophotometric determination of iron using the 1,10-phenanthroline method is a cornerstone technique in environmental and geochemical research. It relies on the formation of a stable, orange-red ferroin complex ([Fe(phen)₃]²⁺) with ferrous iron (Fe²⁺), which can be quantified by its absorbance at 510 nm [4] [19]. This method is prized for its sensitivity, selectivity for Fe²⁺, and overall robustness [20].

A significant challenge, however, arises when this method is applied to samples where iron has been extracted using oxalate-based solutions, a common practice in sequential extraction procedures for quantifying specific iron oxide phases in sediments and soils [4]. In such oxalate-rich matrices, the oxalate anion (C₂O₄²⁻) acts as a potent competing ligand, forming stable complexes with iron (e.g., [Fe(C₂O₄)₃]³⁻) that inhibit the subsequent formation of the colored ferroin complex, leading to substantial analytical underestimation [4].

This Application Note details a novel, robust, and cost-effective pretreatment protocol to overcome this matrix interference. The method is based on a critical pH adjustment step that disrupts the iron-oxalate complex, thereby enabling accurate iron quantification via the standard 1,10-phenanthroline method without the need for sophisticated instrumentation or extensive sample pretreatment [4].

The Mechanism of Interference and Resolution

The Competitive Complexation Environment

In an oxalate-rich extract, a competition exists for the available ferrous and ferric iron. The stability constants of the involved complexes dictate the equilibrium. Oxalate forms a highly stable complex with iron, which, under acidic to neutral conditions, is favored over the ferroin complex. The interference mechanism can be summarized as follows:

- Presence of Oxalate: The extract contains a high concentration of oxalate ions.

- Formation of Iron-Oxalate Complex: Iron (both Fe²⁺ and Fe³⁺) is sequestered into soluble, colorless oxalate complexes ([Fe(C₂O₄)₂]²⁻, [Fe(C₂O₄)₃]³⁻, etc.).

- Suppression of Ferroin Formation: The 1,10-phenanthroline reagent cannot effectively compete for the iron, resulting in weak or no color development.

The pH Adjustment Solution

The proposed method overcomes this interference by leveraging the pH dependence of ligand complexation. By adjusting the pH of the oxalate-rich sample to a weakly alkaline range (pH 7–9) before adding the phenanthroline reagents, the iron-oxalate complex is effectively destabilized [4].

The underlying principle is that in alkaline conditions, the oxalate ion can undergo reactions that reduce its effective concentration for complexing with iron. This shifts the equilibrium, liberating free iron ions. The hydroxylamine hydrochloride simultaneously reduces any Fe³⁺ to Fe²⁺, allowing the 1,10-phenanthroline to form the stable ferroin complex without competitive inhibition [4]. The diagram below illustrates this process and the experimental workflow.

Diagram 1: Visual summary of oxalate interference and the resolving pH adjustment workflow.

Reagents, Materials, and Instrumentation

The Scientist's Toolkit: Essential Research Reagents

Table 1: Key reagents and materials required for the protocol.

| Reagent/Material | Function & Specification | Notes for Preparation |

|---|---|---|

| Ammonium Oxalate Buffer | Common extractant for amorphous/poorly-crystalline iron (hydro)oxides [4]. | Prepared as a 0.2 M solution, pH 3.0-3.2, as per standard sequential extraction protocols. |

| Hydroxylamine Hydrochloride (10% m/v) | A reducing agent that ensures all iron is in the ferrous (Fe²⁺) state, which is necessary for complexation with 1,10-phenanthroline [4]. | Dissolve 10 g of NH₂OH·HCl in 100 mL of deionized water. |

| 1,10-Phenanthroline (0.5% m/v) | The primary complexing agent that forms the orange-red ferroin complex with Fe²⁺ [4] [19]. | Dissolve 0.5 g of 1,10-phenanthroline monohydrate in 100 mL of deionized water. |

| Sodium Hydroxide (10 M & 1 M) or Concentrated Ammonia | Used for the critical pH adjustment step to disrupt the iron-oxalate complex [4]. | Prepare from analytical-grade pellets. Ammonia is an effective alternative. |

| Hydrochloric Acid (25% v/v) | Used for creating an initial acidic environment if needed and for pH adjustment fine-tuning [4]. | Dilute concentrated HCl appropriately. |

| Iron Standard Solution | For calibration curve generation. A stock solution of 1000 mg/L Fe is typical. | Dilute to working standards (e.g., 1-5 mg/L) as required. |

| Deionized Water | Solvent and diluent for all reagents and samples. | Resistivity ≥18 MΩ·cm. |

| Spectrophotometer | Instrument for absorbance measurement of the ferroin complex. | Capable of measurements at 510 nm, using 1 cm pathlength cuvettes. |

| pH Meter | Critical for verifying the pH adjustment to the 7–9 range. | Calibrated with standard buffers. |

Detailed Experimental Protocol

Step-by-Step Procedure for Oxalate-Extractable Iron Measurement

Sample Preparation: Begin with the oxalate-rich extract obtained from your sediment or soil sequential extraction procedure [4]. Ensure the sample is well-mixed.

pH Adjustment (Critical Step):

- Transfer a known volume (e.g., 1-5 mL) of the oxalate extract into a clean test tube or volumetric flask.

- While monitoring with a pH meter, slowly add 10 M sodium hydroxide (NaOH) or concentrated ammonia dropwise with gentle swirling until the pH of the solution is stable within the 7.0 to 9.0 range [4]. This step is crucial for breaking the iron-oxalate complexes.

- Note: A slight precipitate may form but does not typically interfere.

Reduction and Complexation:

Dilution to Volume: Dilute the mixture to the final mark (e.g., 10 mL or 25 mL) with deionized water and mix thoroughly.

Color Development and Measurement:

Calibration:

- Prepare a series of iron standard solutions (e.g., 0, 1, 2, 3, 4, 5 mg/L) by diluting a stock iron standard.

- Subject these standards to the exact same procedure (steps 2-5) as the unknown samples. This is critical as it incorporates the matrix-matching principle, accounting for any residual effects from the reagents.

Data Analysis and Calculation

- Construct a calibration curve by plotting the absorbance of the standards against their known iron concentrations.

- Determine the concentration of iron in the sample extract ([Fe]ₛₐₘₚₗₑ) from the linear regression equation of the calibration curve.

- The concentration of oxalate-extractable iron in the original solid sample can be calculated using the following formula:

Iron (mg/kg) = ([Fe]ₛₐₘₚₗₑ × V × D) / MWhere:[Fe]ₛₐₘₚₗₑ= Iron concentration from calibration curve (mg/L)V= Final volume of the measured solution (L)D= Any additional dilution factorM= Mass of the original solid sample (kg)

Validation and Analytical Performance

The method's validity was confirmed through rigorous testing, demonstrating excellent correlation with theoretical values and robust performance characteristics [4].

Precision and Accuracy

Table 2: Summary of the method's key analytical performance metrics.

| Parameter | Result & Specification | Experimental Conditions |

|---|---|---|

| Optimal pH Range | 7 – 9 | Effective pH window for color development in the presence of oxalate [4]. |

| Linear Range | 1 – 5 mg/L (can be extended to 0.2-10 mg/L) | Abs = 0.1934 × Conc + 0.1360 (R² = 0.9997) [4]. |

| Molar Absorptivity (ε) | ~1.3 × 10⁴ L·mol⁻¹·cm⁻¹ | Confirms the maintained sensitivity of the ferroin complex [4]. |

| Color Stability | >4 days | When stored in a light-proof environment [4]. |

| Accuracy | Strong correlation between measured and theoretical iron concentrations. | Validated with spiked samples and standard reference materials [4]. |

Application Notes and Troubleshooting

- Preservation of Samples: For reproducible results, analyze oxalate extracts promptly after extraction. If storage is necessary, refrigerate and protect from light.

- Reagent Purity: Use analytical-grade reagents and high-purity water to minimize blank interference and background noise.

- Matrix Complexity: For samples with exceptionally high organic matter or other potential interferents, performing a standard addition calibration is recommended to verify accuracy.

- Troubleshooting Low Absorbance:

- Incomplete pH Adjustment: Confirm the final pH after adjustment is firmly within 7-9.

- Insufficient Reduction Time: Ensure the hydroxylamine hydrochloride has adequate time (≥10 min) to reduce all Fe³⁺.

- Incomplete Color Development: Allow the full 10-15 minutes after adding 1,10-phenanthroline before measurement.

- Alternative Applications: This pH-adjustment strategy shows promise for enabling the 1,10-phenanthroline method in other complexing matrices beyond oxalate, increasing the versatility of this classic spectrophotometric technique.

This Application Note presents a validated, simple, and effective protocol for the accurate determination of iron in oxalate-rich extracts using the standard 1,10-phenanthroline method. The core innovation—a single pH adjustment to a weakly alkaline condition (pH 7–9)—effectively neutralizes the primary matrix interference, unlocking the power of this accessible and cost-effective spectrophotometric technique for geochemical and environmental analysis. This method eliminates the need for complex sample pre-treatments or expensive instrumentation, making precise iron quantification accessible to a wider range of laboratories.

This application note provides detailed protocols for the preparation of stock solutions and validation of the linear range for calibration curves, framed within the context of spectrophotometric determination of iron using the phenanthroline complex. Designed for researchers, scientists, and drug development professionals, this guide covers fundamental principles, step-by-step procedures, and best practices to ensure the generation of reliable, high-quality analytical data. The methodologies outlined support robust quantitative analysis, which is fundamental to research and development activities, including pharmaceutical formulation.

In analytical chemistry, a calibration curve (also known as a standard curve) is a fundamental tool used to determine the concentration of an unknown substance by comparing it to a set of standard samples with known concentrations [21]. The relationship between the instrumental response (e.g., absorbance in spectrophotometry) and the analyte concentration is established, allowing for the quantitation of unknowns [21] [22]. The linear range is defined as the concentration interval over which the instrumental response is directly proportional to the concentration of the analyte [23]. For a method to provide results with an acceptable uncertainty, the working range must be established, which may sometimes be wider than the strictly linear range [23].

In the context of the spectrophotometric determination of iron using 1,10-phenanthroline, the iron(II) ions form a red-orange complex with the reagent, which absorbs light strongly in the visible range (~510 nm). The intensity of this color is proportional to the iron concentration, making a calibration curve essential for accurate determination. This document details the protocols for preparing the necessary stock solutions and for rigorously validating the linearity of this relationship.

The Scientist's Toolkit: Essential Research Reagent Solutions

The following table lists the key reagents, materials, and equipment required for the spectrophotometric determination of iron and the construction of a reliable calibration curve.

Table 1: Essential Materials and Reagents for Iron Determination via Phenanthroline Complex Method

| Item | Function/Brief Explanation |

|---|---|

| 1,10-Phenanthroline | The complexing agent that reacts with Fe²⁺ ions to form the stable red-orange [Fe(phen)₃]²⁺ complex, which is measured spectrophotometrically. |

| Iron Standard (e.g., Ferrous Ammonium Sulfate) | A high-purity compound used to prepare a primary stock solution with a precisely known concentration of iron. |

| Hydroxylamine Hydrochloride | A reducing agent added to ensure all iron is in the ferrous (Fe²⁺) state before complexation with phenanthroline. |

| Sodium Acetate Buffer | Maintains the reaction pH between 3 and 9 (optimal ~4-5) for stable and quantitative complex formation. |

| Volumetric Flasks | Used for preparing stock and standard solutions with high precision and accuracy. |

| Pipettes and Tips | For accurate measurement and transfer of specific liquid volumes during serial dilution. |

| UV-Vis Spectrophotometer | The instrument used to measure the absorbance of the iron-phenanthroline complex at a specific wavelength (~510 nm). |

| Cuvettes | Sample holders for the spectrophotometer; compatible with the visible wavelength range. |

Experimental Protocols

Protocol 1: Preparation of Stock and Standard Solutions

A accurately prepared stock solution is the critical first step for a reliable calibration curve.

Materials:

- Primary iron standard (e.g., high-purity ferrous ammonium sulfate, Fe(NH₄)₂(SO₄)₂·6H₂O)

- 1,10-Phenanthroline solution (e.g., 0.1% w/v in water)

- Hydroxylamine hydrochloride solution (e.g., 10% w/v in water)

- Sodium acetate buffer (e.g., 1 M, pH ~4.5)

- Deionized water

- Analytical balance

- Volumetric flasks (e.g., 100 mL, 50 mL, multiple 25 mL)

- Precision pipettes and tips

Procedure:

- Primary Stock Solution: Accurately weigh approximately 0.07 g of ferrous ammonium sulfate (exact mass recorded to 0.1 mg) and transfer quantitatively into a 100 mL volumetric flask. Dissolve and dilute to the mark with deionized water. Calculate the exact concentration of iron in this stock solution in µg/mL. (Note: The molecular weight of Fe(NH₄)₂(SO₄)₂·6H₂O is 392.14 g/mol, and the atomic weight of Fe is 55.85 g/mol).

- Intermediate Stock Solution: Pipette 10.0 mL of the primary stock solution into a 50 mL volumetric flask and dilute to the mark with deionized water. This intermediate dilution expands the dynamic preparation range.

- Working Standard Solutions (Calibration Standards): Using a serial dilution technique, prepare a minimum of five standard solutions covering the expected linear range (e.g., 0.5 - 5.0 µg/mL Fe). Label a series of 25 mL volumetric flasks.

- Pipette appropriate volumes of the intermediate stock solution (e.g., 0.5, 1.0, 2.0, 3.0, 4.0, 5.0 mL) into each flask.

- To each flask, add in sequence:

- 1.0 mL of hydroxylamine hydrochloride solution (to reduce Fe³⁺ to Fe²⁺).

- 2.0 mL of the 1,10-phenanthroline solution.

- 5.0 mL of sodium acetate buffer.

- Dilute each flask to the 25 mL mark with deionized water and mix thoroughly.

- Allow the color to develop for at least 15 minutes before measurement.

Protocol 2: Establishing the Calibration Curve and Assessing the Linear Range

This protocol describes how to generate the calibration data and statistically evaluate the linear range.

Materials:

- Prepared working standard solutions (from Protocol 1)

- UV-Vis Spectrophotometer

- Cuvettes

- Computer with data plotting software (e.g., Microsoft Excel)

Procedure:

- Spectrophotometer Measurement:

- Set the spectrophotometer to the appropriate wavelength (510 nm for the iron-phenanthroline complex).

- Using a reagent blank (containing all reagents except the iron standard) in a cuvette, zero the instrument.

- Measure the absorbance of each working standard solution, ideally in triplicate, to account for minor procedural variations [22].

- Record all absorbance values.

Data Analysis and Curve Fitting:

- Calculate the average absorbance for each standard concentration.

- Plot the data with absorbance on the y-axis and concentration (µg/mL) on the x-axis [21] [22].

- Using statistical software, perform a least-squares linear regression analysis on the data to obtain the best-fit line with the equation y = mx + b, where

mis the slope andbis the y-intercept [21] [22]. - Calculate the coefficient of determination (R²) to quantify the goodness of fit. An R² value >0.999 is typically indicative of excellent linearity in analytical methods [24] [22].

Linear Range Validation:

- The linear range is the concentration interval over which the analyte response is directly proportional to its concentration [23]. Visually inspect the plot for deviations from linearity.

- The calibration curve should be linear across the entire prepared range, covering 0-150% or 50-150% of the expected analyte concentration in unknown samples [23].

- Examine the plot for a non-linear section, known as the limit of linearity (LOL), which indicates the instrument is nearing saturation at high concentrations [22]. The validated linear range for the iron-phenanthroline method is typically from the limit of quantitation up to this LOL.

Table 2: Example Data Table for Iron-Phenanthroline Calibration Curve

| Standard Solution | Iron Concentration (µg/mL) | Absorbance (Replicate 1) | Absorbance (Replicate 2) | Absorbance (Replicate 3) | Mean Absorbance | Standard Deviation |

|---|---|---|---|---|---|---|

| Blank | 0.00 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| 1 | 0.50 | 0.125 | 0.127 | 0.124 | 0.125 | 0.0015 |

| 2 | 1.00 | 0.248 | 0.251 | 0.249 | 0.249 | 0.0015 |

| 3 | 2.00 | 0.501 | 0.498 | 0.503 | 0.501 | 0.0025 |

| 4 | 3.00 | 0.749 | 0.752 | 0.748 | 0.750 | 0.0020 |

| 5 | 4.00 | 0.998 | 1.002 | 0.999 | 1.000 | 0.0020 |

| 6 | 5.00 | 1.250 | 1.247 | 1.252 | 1.250 | 0.0025 |

Linear Regression Result: y = 0.250x + 0.001; R² = 0.9999

Workflow Diagram: Calibration Curve Generation and Validation

The following diagram illustrates the logical workflow for creating and validating a calibration curve, from initial preparation to final acceptance for use in sample analysis.

Discussion and Best Practices

Critical Considerations for Linear Range

- Deviations from Linearity: At high concentrations, deviations from linearity can occur due to analyte or matrix effects causing instrumental saturation, analogous to the "self-absorbance" phenomenon in Beer's law [25]. For the iron-phenanthroline complex, this could manifest as a "turning over" or plateau of the absorbance signal at high iron concentrations [25]. If the linear range is too narrow, samples may require dilution to fall within the validated range [23].

- Matrix Effects: The linear range should be confirmed in the presence of the sample matrix, as other components can interfere with the complex formation or absorbance measurement [23] [24]. For instance, in a complex sample, the calibration curve is best prepared using the blank matrix (e.g., supernatant of unloaded nanoparticles in pharmaceutical development) to ensure accuracy [24].

Troubleshooting and Method Validation

- Precision and Accuracy: To fully validate the method, assess intra-day (repeatability) and inter-day (intermediate precision) precision by measuring quality control samples at low, mid, and high concentrations within the linear range on the same day and over different days [24]. Accuracy is typically determined via recovery studies, where a known amount of analyte is spiked into the matrix, and the measured value is compared to the theoretical value [24].

- Common Pitfalls:

- Inaccurate Stock Solution: The purity of the starting material and precise weighing are paramount.

- Poor Pipetting Technique: This is a major source of error in serial dilutions. Use calibrated pipettes and change tips between each standard.

- Incorrect pH: The iron-phenanthroline complex formation is pH-dependent. Ensure the buffer is functioning correctly.

- Insufficient Color Development Time: Allow adequate time for the red-orange complex to form completely before measurement.

Adherence to the detailed protocols for stock solution preparation and linear range validation outlined in this application note is fundamental for obtaining reliable quantitative results in the spectrophotometric determination of iron using the phenanthroline complex. A rigorously constructed and validated calibration curve, characterized by a high coefficient of determination (R²) and a demonstrated linear range suitable for the intended samples, forms the bedrock of defensible analytical data. These best practices ensure method robustness, directly contributing to the integrity and success of research and development projects.

The accurate determination of iron concentration is a critical analytical procedure in environmental monitoring, clinical chemistry, and pharmaceutical quality control. Spectrophotometric methods, prized for their cost-effectiveness, simplicity, and sensitivity, are widely employed for this purpose [26]. Among these, the 1,10-phenanthroline method stands as a classical technique for iron quantification. This application note details tailored protocols for determining iron in groundwater, biological serum, and pharmaceutical samples using the phenanthroline complex, framing these methods within ongoing research to enhance their robustness, overcome analytical interference, and enable field-portable applications.

The Scientist's Toolkit: Key Research Reagent Solutions

The following table catalogues essential reagents and materials required for the spectrophotometric determination of iron.

Table 1: Essential Reagents and Materials for Iron Determination

| Reagent/Material | Function/Brief Explanation |

|---|---|

| 1,10-Phenanthroline | Primary complexing agent; forms a stable orange-red complex (ferroin) with Fe²⁺ for measurement [4] [27]. |

| Hydroxylamine Hydrochloride | Reducing agent; ensures all iron is in the ferrous (Fe²⁺) state prior to complexation [4]. |

| Sodium Acetate/Acetic Acid | Buffer system; maintains the solution at the optimal pH (~3.5-7) for complex formation [4] [2]. |

| Desferrioxamine B (DFO) | Alternative complexing agent; forms a stable 1:1 complex with Fe³⁺, allowing direct total iron measurement without pre-reduction [26]. |

| Ammonia/Sodium Hydroxide | pH adjustment; critical for overcoming oxalate interference in sequential extraction samples [4]. |

| Oxalate Solution | Key extractant in sequential extraction procedures for speciating iron oxides in sediments [4]. |

| Triethylenetetramine (Trien) | Masking agent; eliminates copper interference in the 1,10-phenanthroline method [28]. |

Application-Specific Protocols & Data

Protocol 1: Iron Determination in Groundwater

The determination of iron in groundwater is vital for assessing water quality and compliance with safety standards, such as the WHO guideline of 0.3 mg/L [15].

Detailed Protocol:

- Sample Collection: Collect groundwater samples in clean, acid-washed polyethylene bottles. Acidify to pH < 2 with high-purity hydrochloric acid for preservation if analysis is not immediate [15].

- Reagent Preparation:

- Prepare a 10% (m/v) hydroxylamine hydrochloride solution in water.

- Prepare a 0.5% (m/v) 1,10-phenanthroline solution in ethanol.

- Prepare an acetate buffer by mixing sodium acetate and acetic acid to achieve pH ~4.5.

- Sample Pretreatment: Convert all iron to the soluble ferrous form. For total iron, ensure sample digestion if particulate iron is present.

- Color Development:

- Pipette a known volume (e.g., 50 mL) of sample into a clean flask.

- Add 1 mL of hydroxylamine hydrochloride solution and mix.

- Add 5 mL of the acetate buffer and 2 mL of the 1,10-phenanthroline solution.

- Dilute to the mark in a volumetric flask and allow 10-15 minutes for full color development.

- Absorbance Measurement: Measure the absorbance of the solution at 510 nm against a reagent blank using a spectrophotometer [15].

- Quantification: Determine the iron concentration from a calibration curve prepared with iron standard solutions treated identically to the samples.

Table 2: Performance Data for Groundwater Analysis (Orthophenanthroline Method)

| Parameter | Value/Result |

|---|---|

| Linear Range | 0.2 - 10 mg/L [4] |

| Correlation Coefficient (R²) | 0.9997 [4] |

| Molar Absorptivity (ε) | ~1.3 × 10⁴ L/mol·cm [4] |

| Reported Groundwater Concentrations | 0.03 - 0.37 mg/L [15] |

Figure 1: Groundwater analysis workflow for iron determination.

Protocol 2: Iron Determination in Serum

Monitoring iron in biological fluids like serum is crucial for diagnosing medical conditions. Desferrioxamine B (DFO) offers a robust method for total iron determination.

Detailed Protocol:

- Reagent Preparation: Prepare a 0.008 M Desferrioxamine B (DFO) solution in water.

- Sample and Standard Preparation:

- For serum samples, a deproteinization step may be required.

- Prepare a series of iron standard solutions from a commercial ICP standard (e.g., 1000 mg/L).

- Complex Formation:

- Pipette a known volume of sample or standard into a 25 mL volumetric flask.

- Add 5 mL of the 0.008 M DFO solution to ensure a ligand excess.

- Add a sufficient volume of NaOH (e.g., 0.1 M) to neutralize any acid from the standard and to achieve a final pH between 6.8 and 7.1, optimal for the [FeLH]+ complex.

- Dilute to the mark with water and mix thoroughly.

- Absorbance Measurement: Measure the absorbance of the intensely red-colored complex at its maximum absorption wavelength (~430-440 nm for the DFO complex) [26].

- Quantification: Calculate the total iron concentration in the unknown sample from a calibration curve. DFO automatically complexes with Fe³⁺, and any Fe²⁺ present is oxidized and complexed, providing the total iron content directly [26].

Table 3: Performance Data for Serum Analysis (DFO Method)

| Parameter | Value/Result |

|---|---|

| Linear Range | 4.5×10⁻⁵ M - 8×10⁻⁴ M [26] |

| Applicability | Control human urine and control serum [26] |

| Key Advantage | Single-step total iron determination, no pre-reduction needed [26] |

Protocol 3: Analysis in Complex Matrices and Pharmaceutical Samples

Analysis often faces challenges like interfering ions or complex sample matrices. Research has developed specific strategies to address these.

Overcoming Oxalate Interference in Sequential Extractions: A major research advancement enables the 1,10-phenanthroline method for iron extracted by oxalate, a common reagent in sediment sequential extraction [4].

- Interference: Oxalate competes with 1,10-phenanthroline for iron, inhibiting color development.

- Solution: After oxalate extraction, adjust the solution pH to 7–9 using sodium hydroxide or concentrated ammonia. This pH adjustment effectively negates the interference, allowing the ferroin complex to form stably for up to 4 days when kept in a light-proof environment [4].

Analysis of Pharmaceutical Formulations: An indirect method was developed for theophylline based on its oxidation and reaction with the iron(II)-bathophenanthroline complex.

- Oxidation: Theophylline is oxidized with a known excess of cerium sulfate in acidic medium.

- Complex Decomposition: The remaining unreacted cerium sulfate reacts with and decomposes the red-colored iron(II)-bathophenanthroline complex.

- Measurement: The absorbance of the remaining complex is measured at 534 nm. The decrease in color intensity is directly proportional to the theophylline concentration [29].

Table 4: Advanced Method Performance in Complex Matrices

| Application/Method | Key Parameter | Value/Result |

|---|---|---|

| Oxalate-Extractable Iron [4] | Optimal pH for interference removal | 7 - 9 |

| Color stability after pH adjustment | Up to 4 days (light-proof) | |

| Theophylline via Bathophenanthroline [29] | Linear Range | 2 - 23 µg/mL |

| Molar Absorptivity (ε) | 14,809 L/mol·cm |

Figure 2: Methodologies for analyzing complex matrices and pharmaceuticals.

Emerging Research & Portable Sensing

Recent research extends these principles into developing low-cost, field-portable instrumentation. One such device is an Iron Measurement System (IMS) based on the phenanthroline method [2].

- Design: It utilizes a paired emitter detector diode (PEDD) setup with an RGB LED and a photodiode sensor to measure absorption through the ferroin complex.

- Performance: The IMS demonstrated a sensitivity of 2.5 µg/L and a linear response from 25 to 1000 µg/L, making it suitable for direct field compliance checking with regulatory limits (e.g., the EU directive of 200 µg/L) [2]. This aligns with the broader thesis goal of making robust iron quantification more accessible and adaptable beyond the traditional laboratory.

The spectrophotometric determination of iron using phenanthroline and related complexes remains a versatile and vital analytical technique. The protocols detailed herein for groundwater, serum, and complex pharmaceutical samples, supported by data on overcoming interferences and leveraging novel complexing agents, provide a practical guide for researchers. Furthermore, the ongoing evolution of this field—from fundamental chemical solutions to interference masking and portable sensor design—highlights its dynamic nature and continued relevance in modern analytical science.

Ensuring Precision and Accuracy: Troubleshooting Common Pitfalls

The spectrophotometric determination of iron utilizing the 1,10-phenanthroline complex is a foundational method in analytical chemistry, valued for its sensitivity and selectivity [30]. The formation of a stable, orange-red tris(1,10-phenanthroline)iron(II) complex, commonly known as ferroin, provides the basis for quantitative analysis [31]. The reliability of this determination, however, is profoundly dependent on the precise control of experimental conditions. The stability of the Fe(II)-phenanthroline complex, and consequently the accuracy of the spectrophotometric measurement, can be significantly influenced by parameters such as pH, temperature, and light [4].

Understanding and optimizing these critical parameters is not merely an academic exercise but a practical necessity for researchers, scientists, and drug development professionals. In contexts ranging from quality control of pharmaceutical iron supplements [18] to environmental analysis of iron species in sediments [4], failure to control these factors can introduce substantial error. This application note, framed within broader thesis research on the spectrophotometric determination of iron, provides a detailed investigation into the effects of these parameters. It offers optimized protocols and structured data to ensure the highest levels of precision and accuracy in analytical results.

Effects of Critical Parameters on Complex Stability