The Race Against Time

Decoding the Invisible Dance of Fiber Solidification

Article Navigation

Why Fibers Aren't Born Strong

Imagine a spider spinning silk 30 times thinner than a human hair, yet stronger than steel. Or hagfish unleashing a defensive slime that transforms seawater into a suffocating gel in milliseconds. These natural marvels depend on a hidden process: fiber solidification kinetics—the precise science of how liquid precursors transform into solid fibers 7 .

Natural Fiber Marvels

Spider silk and hagfish slime demonstrate nature's mastery of fiber solidification.

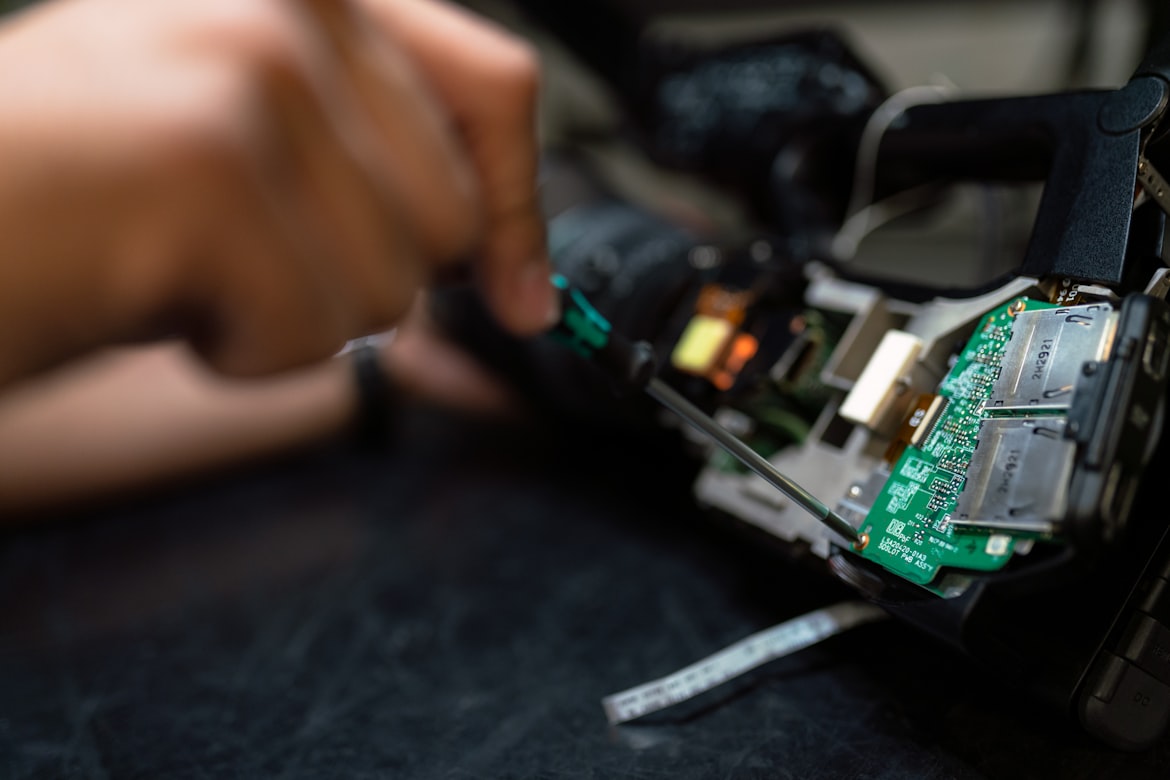

Synthetic Fiber Production

Engineers face challenges in controlling solidification kinetics for synthetic fibers.

The Physics of Transformation: From Soup to Thread

Diffusion's Double-Edged Sword

Solidification begins when a liquid polymer or molten metal loses solvent, cools, or reacts chemically. Diffusion—the random walk of molecules—drives this process 1 .

Extensional Flow: The Stress Test

In 2010, scientists pioneered a breakthrough method to probe solidification in real-time using extensional flow—a stretching force akin to pulling taffy 1 .

The Microstructure Crucible

When titanium alloy fibers cool at >1,000°C/s, atoms freeze mid-diffusion, creating metastable phases with 1.8 GPa strength—rivaling aerospace alloys 3 .

Inside a Landmark Experiment: The Extensional Flow Breakthrough

Methodology: Snapping Fibers to Measure Strength

Researchers designed a microfluidic "torture chamber" for fibers:

- Injection: Aqueous carbon nanotube (CNT) dispersion injected into flowing polyvinyl alcohol (PVA) solution.

- Coagulation: CNTs clump via "bridging coagulation" as PVA chains adsorb onto their surfaces.

- Constriction Test: Fibers passed through diameter constrictions (2.4 mm → 1.5 mm).

- Residence Time Control: By adjusting the distance to constriction (Tres), solidification progress was mapped 1 .

Results: The Three Regimes of Fragility

| Residence Time (Tres) | Survival Rate | Fragment Length (μm) |

|---|---|---|

| 5 sec | 0% | 80 ± 12 |

| 12 sec | 45% | 120 ± 18 |

| 20 sec | 100% | N/A (no breakage) |

Data revealed a critical threshold: Tres >12 sec granted fibers enough strength to endure ~4.3 s⁻¹ strain rates 1 .

The Scientist's Toolkit: Engineering Solidification

| Material/Tool | Function | Innovation |

|---|---|---|

| Micro granular gel | Support medium for 3D printing | Enables solvent exchange, printing 1.5 μm fibers at 5 mm/s 7 |

| Nickel-coated fibers | Reinforce metal matrix composites (MMCs) | Cools faster, reduces grain size by 40%, prevents interfacial cracks |

| PVA-CNT ink | Precursor for wet-spun nanocomposites | Bridging coagulation creates load-transfer networks 1 |

| High-Gravity Furnaces | Rapid solidification environment | Achieves cooling rates >10⁶ K/m for ultrafine grains 9 |

Numerical Revolution

Advanced models predict kinetics without trial-and-error:

- Cellular Automata (CA): Simulates grain growth around fibers during metal solidification .

- KGT Model: Maps columnar-to-equiaxed grain transitions in alloys under laser melting 9 .

| Model | Predicted | Actual Outcome | Error |

|---|---|---|---|

| CA-FE (ProCAST®) | Grain density in Al-MMC | 1.2×10⁵ grains/mm³ | <5% |

| KGT Thermokinetics | CET in Alnico-8H | Equiaxed dominance | <8% |

Tomorrow's Fibers: From Space Stations to Smart Textiles

Zero-G Solidification

Aboard China's Space Station, microgravity eliminates convection, letting scientists grow defect-free single-crystal fibers for quantum devices 4 .

Self-Healing Networks

Plant fiber-reinforced geopolymers use cellulose to "stitch" microcracks, boosting strength by 29% 8 .

AI-Driven Kinetics

Machine learning predicts optimal solidification paths for bespoke fibers—stretchable sensors or impact-resistant armor 6 .

The Grand Challenge

Mimicking hagfish slime skeins—1 μm threads unraveling in 400 ms. Current 3D printing via solvent exchange (3DPX) hits 1.5 μm fibers, but nature's speed remains unmatched 7 .

Conclusion: The Invisible Clockmaster

Fiber solidification is a race against invisible clocks: diffusion clocks, thermal clocks, stress clocks. By choreographing these kinetics, scientists transform chaotic molecular dances into silk, carbon nanotubes, or titanium wires. As one researcher mused, "We're not just making fibers—we're teaching liquids how to remember their shape." From spider silk's patience to hagfish's haste, nature's stopwatch holds the blueprints for tomorrow's materials.