Layer-by-Layer Self-Assembly for Advanced Hybrid Photocatalysts: Fabrication, Optimization, and Biomedical Applications

This article provides a comprehensive examination of the Layer-by-Layer (LbL) self-assembly technique for fabricating sophisticated hybrid photocatalysts.

Layer-by-Layer Self-Assembly for Advanced Hybrid Photocatalysts: Fabrication, Optimization, and Biomedical Applications

Abstract

This article provides a comprehensive examination of the Layer-by-Layer (LbL) self-assembly technique for fabricating sophisticated hybrid photocatalysts. Tailored for researchers and scientists in materials science and drug development, it explores the foundational principles of LbL, details advanced methodologies for constructing diverse nanoarchitectures like Z-scheme heterojunctions, and addresses key challenges in optimization and stability. Further, it critically validates performance through comparative analysis and discusses the direct implications of these advanced materials for environmental remediation, particularly the degradation of antibiotic contaminants, and potential biomedical applications.

Understanding Layer-by-Layer Self-Assembly: Principles, Forces, and Material Choices

Layer-by-Layer (LbL) self-assembly has emerged as a powerful and versatile methodological platform for the precise fabrication of nanoscale thin films and hybrid functional materials. As a quintessential nanoarchitectonics approach, LbL enables the bottom-up construction of highly ordered, multilayered structures through the sequential adsorption of complementary components [1]. The technique was fundamentally developed to create organized molecular architectures by exploiting various intermolecular interactions, with electrostatic attraction between oppositely charged species representing the most classical driving force [1].

The generic advantages of LbL assembly include its simplicity, versatility, and scalability, which have positioned it as an indispensable tool in materials science [1]. Unlike other bottom-up methods such as Langmuir-Blodgett (LB) deposition or self-assembled monolayers (SAMs), which suffer from limitations including substrate dependence and tedious assembly procedures, LbL assembly offers unprecedented material selectivity and operational flexibility [1]. This technique allows researchers to precisely control composition, structure, and thickness at the nanoscale level by simply varying the number of deposition cycles, concentration of solutions, and processing conditions [1].

In the context of hybrid photocatalyst fabrication, LbL assembly provides an exceptional platform for designing spatially multilayered nanoarchitectures with tailored optical, electronic, and catalytic properties. The ability to engineer interfaces at the molecular level makes LbL particularly valuable for creating advanced photocatalytic systems that address fundamental challenges in charge carrier separation, light absorption efficiency, and long-term operational stability [1] [2].

Fundamental Principles and Mechanisms

Molecular Interactions Driving LbL Assembly

The LbL technique operates through various molecular recognition and interaction mechanisms that facilitate the alternating deposition of materials. While initially developed based on electrostatic interactions, the methodology has expanded to encompass multiple driving forces:

- Electrostatic Interactions: The classical LbL approach utilizes alternating adsorption of oppositely charged polyelectrolytes or nanoparticles, driven primarily by enthalpy and entropy changes [1].

- Hydrogen Bonding: Certain LbL systems employ hydrogen-bonding interactions between complementary molecular species, particularly for biological or organic components.

- Covalent Bonding: Click chemistry and other covalent coupling strategies can create exceptionally stable LbL architectures with enhanced mechanical and chemical robustness.

- Biological Affinity Interactions: Specific binding pairs such as antigen-antibody, biotin-avidin, or DNA hybridization enable highly selective and precise molecular assembly [1].

The LbL process typically begins with a charged substrate, which is alternately immersed in solutions containing positively and negatively charged materials. Between each deposition step, rinsing removes loosely adsorbed species, ensuring controlled layer growth [1]. This cyclical process can be repeated numerous times to build films of precisely controlled thickness and composition.

LbL Assembly Workflow

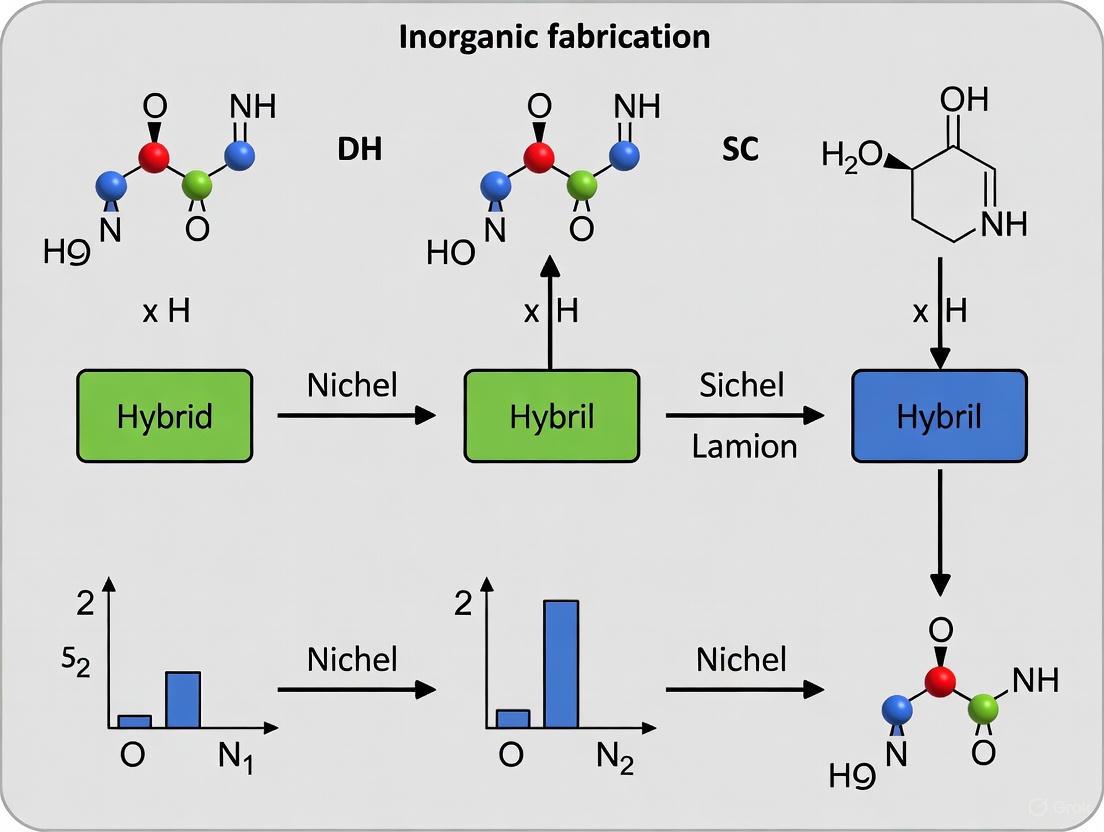

The following diagram illustrates the fundamental LbL self-assembly process:

Experimental Protocols for Photocatalyst Fabrication

LbL Stabilization of Plasmonic Photocatalysts

Objective: To create stable, solar-active hybrid photocatalysts by applying protective polymer shells onto plasmonic nanoparticles using the LbL technique [2].

Materials:

- Plasmonic metal nanoparticles (e.g., Au-Ag composite NPs)

- Polycation solution: Polyallylamine hydrochloride (PAH, 17.5 kDa) in deionized water

- Polyanion solution: Polyacrylic acid (PAA, 2 kDa) in deionized water

- TiO2 substrates (P25, PC500, or pure anatase)

- Deionized water for rinsing

- Ethanol for suspension

Procedure:

- Synthesis of Plasmonic Nanoparticles: Prepare nine colloidal spherical Auâ‚“Agâ‚â‚“ nanoparticle suspensions (x ranging from 0.2 to 1) using a modified Turkevich method [2].

- Formation of 'Rainbow' Mixture: Combine equal amounts of each nanoparticle suspension to create a broadband plasmonic 'rainbow' mixture [2].

- LbL Stabilization Process: a. Centrifuge the nanoparticle solution at 10,000× g for 15 minutes and resuspend in deionized water. b. Add PAH solution (concentration: 2 mg/mL in 0.5 M NaCl) to the nanoparticle suspension and incubate for 15 minutes with gentle stirring. c. Centrifuge and wash twice with deionized water to remove excess PAH. d. Add PAA solution (concentration: 2 mg/mL in 0.5 M NaCl) to the nanoparticles and incubate for 15 minutes. e. Centrifuge and wash twice with deionized water. f. Repeat steps b-e to apply four protective layers (2× PAH and 2× PAA) [2].

- Photocatalyst Assembly: Load 2 wt% of LbL-stabilized plasmonic nanoparticles onto TiO2 (P25) via photoimpregnation under UV-A illumination with vigorous stirring for at least 1.5 hours [2].

- Post-treatment: Centrifuge the resulting suspension (10,000× g; 15 minutes), wash, and dry overnight at 105°C. Crush the dried powder using pestle and mortar.

Characterization:

- UV-vis spectroscopy to confirm plasmon absorption bands (300-800 nm range)

- Nâ‚‚ sorption analysis for Brunauer-Emmett-Teller (BET) surface area measurement

- Diffuse reflectance spectroscopy (DRS) with Kubelka-Munk transformation for band gap calculation

LbL Assembly of ZnO NPs-PbS QDs Thin Films

Objective: To construct quantum dot-sensitized thin films for enhanced photosensitization using LbL assembly [1].

Materials:

- ZnO nanoparticles (NPs)

- PbS quantum dots (QDs)

- Polyacrylic acid (PAA)

- Appropriate solvents (water, ethanol)

- Charged substrate (e.g., glass, silicon wafer)

Procedure:

- Substrate Preparation: Clean substrate thoroughly and functionalize with negative surface charges.

- ZnO/PAA Base Layer Formation: a. Immerse substrate in ZnO NP suspension (positively charged) for 10 minutes. b. Rinse with deionized water to remove loosely adsorbed nanoparticles. c. Immerse in PAA solution (negatively charged) for 10 minutes. d. Rinse with deionized water. e. Repeat steps a-d to build the desired number of base layers.

- Quantum Dot Sensitization: Deposit PbS QDs onto the ZnO/PAA LbL-assembled film by immersing in QD solution for specified duration.

- Characterization: Analyze photoelectrochemical performance and spectral response.

Essential Research Reagent Solutions

Table 1: Key Research Reagents for LbL Photocatalyst Fabrication

| Reagent/Material | Function/Application | Key Characteristics |

|---|---|---|

| Polyallylamine hydrochloride (PAH) | Polycation for LbL assembly; forms protective shells around plasmonic NPs [2] | Molecular weight: 17.5 kDa; creates positive surface charge |

| Polyacrylic acid (PAA) | Polyanion for LbL assembly; partners with PAH for protective layering [2] | Molecular weight: 2 kDa; creates negative surface charge |

| AuxAg1-x Nanoparticles | Plasmonic component for broadband solar absorption [2] | Bimetallic composition (x=0.2-1); enables 'rainbow' photocatalysis |

| TiO2 (P25) | Semiconductor substrate for photocatalysis [2] | ~80% anatase, ~20% rutile; high photocatalytic activity |

| PbS Quantum Dots | Photosensitizer for extended spectral response [1] | Narrow bandgap; enhances visible/NIR absorption |

| ZIF-67 | Metal-organic framework precursor for advanced heterostructures [3] | Multi-faceted cage structure; excellent light response and stability |

Performance Analysis and Applications

Quantitative Performance of LbL-Stabilized Photocatalysts

Table 2: Performance Comparison of LbL-Stabilized vs. Non-Stabilized Photocatalysts

| Photocatalyst System | Performance Metric | Results | Stability Assessment |

|---|---|---|---|

| P25 + 2 wt% LbL-'rainbow' | Stearic acid degradation under simulated sunlight [2] | 56% more efficient vs. pristine P25 | Retained nearly all initial activity after 1 month aging |

| Non-stabilized equivalent | Stearic acid degradation under simulated sunlight [2] | Baseline performance | Lost 34% of initial activity after 1 month aging |

| LbL-stabilized metals | Stability under heated oxidative atmosphere [2] | Superior stability maintained | Highly resistant to aggregation and oxidation |

| ZnO NPs-PbS QDs thin films | Photosensitization efficiency [1] | Enhanced spectral response | Improved structural integrity vs. non-assembled systems |

The application of LbL-stabilized plasmonic 'rainbow' nanoparticles on TiOâ‚‚ (P25) with 2 wt% metal loading demonstrated exceptional performance, showing 56% greater efficiency in stearic acid degradation compared to pristine P25 under simulated sunlight (AM 1.5G) [2]. Furthermore, the techno-economic analysis identified this composite as the most cost-effective configuration [2].

Advanced Photocatalytic Applications

LbL-assembled hybrid photocatalysts have demonstrated remarkable performance across various applications:

- Environmental Remediation: Hierarchical double S-type heterojunction photocatalysts fabricated through LbL-related approaches have achieved degradation efficiencies of 93.13% for antibiotics like norfloxacin, with mineralization rates of 85.81% [3].

- Solar Water Splitting: LbL-engineered interfaces significantly enhance charge separation efficiency, a critical factor in photocatalytic hydrogen production [4] [1].

- COâ‚‚ Reduction: The precise control over interfacial properties enables the design of catalysts with improved selectivity and efficiency for carbon fixation processes [5].

The following diagram illustrates the charge transfer mechanism in a complex LbL-fabricated heterojunction photocatalyst:

Technical Considerations and Optimization

Critical Parameters for LbL Assembly

Successful implementation of LbL nanoarchitectonics requires careful optimization of several parameters:

- Solution Conditions: pH, ionic strength, and concentration significantly impact layer growth and morphology. For polyelectrolyte systems, 0.5 M NaCl concentration provides optimal charge screening [2].

- Deposition Time: Typically 10-20 minutes per layer ensures sufficient adsorption while maintaining efficiency [1].

- Rigorous Washing: Essential for removing loosely bound species and preventing cross-contamination between layers [1] [6].

- Layer Number Control: Precisely determines final film thickness and properties; 4 layers (2× PAH and 2× PAA) provided optimal stabilization for plasmonic nanoparticles [2].

Characterization Methodologies

Comprehensive characterization is crucial for evaluating LbL-fabricated photocatalysts:

- Optical Analysis: UV-vis spectroscopy and diffuse reflectance spectroscopy (DRS) quantify light absorption characteristics and band gap energies [2].

- Surface Analysis: Nâ‚‚ sorption (BET) measurements determine specific surface area and porosity [2].

- Electron Microscopy: Reveals morphological features and layer uniformity at nanoscale resolution.

- X-ray Photoelectron Spectroscopy (XPS): Provides chemical state information and verifies successful layer deposition [3].

- Photocatalytic Activity Testing: Standardized degradation tests (e.g., stearic acid degradation, antibiotic removal) under controlled illumination quantify performance [2] [3].

The LbL self-assembly technique represents a foundational nanoarchitectonics approach with exceptional versatility for fabricating advanced hybrid photocatalysts. Through precise control over molecular arrangement and interfacial engineering, researchers can design materials with enhanced light absorption, efficient charge separation, and improved long-term stability—key attributes for addressing global energy and environmental challenges.

The precise engineering of thin films through layer-by-layer (LbL) self-assembly has emerged as a foundational technique for fabricating advanced hybrid photocatalysts. The controlled integration of diverse nanomaterials—including metal oxides, carbon-based materials, and polymers—into stratified architectures is governed by specific molecular interactions. These interactions, namely electrostatic forces, hydrogen bonding, and non-electrostatic forces, dictate the adsorption kinetics, structural stability, and ultimate functionality of the composite material. This Application Note provides a detailed quantitative framework and standardized protocols for leveraging these driving forces to construct photocatalysts for applications in energy conversion and environmental remediation. The principles outlined are designed to equip researchers with the methodologies to systematically design and optimize LbL-assembled photocatalytic systems.

Theoretical Framework & Quantitative Interaction Parameters

The formation and stability of LbL films are governed by a suite of non-covalent interactions. The chemical energy released in the formation of these interactions is typically on the order of 1–5 kcal/mol, but can be significantly higher for specific strong interactions [7]. The table below summarizes the key parameters of these forces.

Table 1: Key Characteristics of Primary Interactions in LbL Self-Assembly

| Interaction Type | Strength Range (kcal/mol) | Key Features | Role in LbL Self-Assembly |

|---|---|---|---|

| Electrostatic (Ionic) | ~1-5 (can be higher) [7] | Attraction between ions or molecules with full, permanent opposite charges; influenced by pH and ionic strength [8]. | Primary driving force for traditional polyelectrolyte deposition; enables charge overcompensation and reversal [9]. |

| Hydrogen Bonding | ~0-4 (can reach 40) [7] | Attraction between a H atom bonded to O, N, F and a lone pair on another O, N, F atom [7] [10]. | Provides directionality and specificity; used for assembling non-ionic materials like H-bonded organic frameworks (HOFs) [11]. |

| π–π Stacking | ~2-3 [7] | Interaction between π-orbitals of aromatic systems; configurations include edge-to-face and offset stacking [7]. | Facilitates electron transfer and enhances structural stability in organic frameworks and carbon-based composites [11]. |

| Van der Waals Forces | < 1-2 [7] | Includes London dispersion forces (induced dipole-induced dipole); always present and additive [7]. | Contributes to cohesion, particularly in layers of non-polar molecules or polymers; significant in multilayer structures [7]. |

| Hydrophobic Effect | Not Applicable (Entropy-driven) | Entropy-driven aggregation of non-polar molecules in water to minimize hydrophobic surface area [7]. | Can drive the assembly of hydrophobic building blocks and influence the adsorption of organic pollutants during photocatalysis [12]. |

Experimental Protocols for LbL Photocatalyst Fabrication

This section provides detailed methodologies for fabricating hybrid photocatalysts using different interaction-driven LbL assembly techniques.

Protocol: Electrostatic LbL Assembly on Planar Substrates

This is the canonical LbL method for building multilayer thin films, primarily driven by electrostatic attraction between oppositely charged polyelectrolytes and nanoparticles [9] [13].

Research Reagent Solutions:

- Cationic Poly electrolyte Solution: Poly(allylamine hydrochloride) (PAH), 1-2 mg/mL in 0.5 M NaCl aqueous solution.

- Anionic Poly electrolyte Solution: Poly(sodium 4-styrenesulfonate) (PSS), 1-2 mg/mL in 0.5 M NaCl aqueous solution.

- Photocatalytic Nanoparticle Suspension: e.g., TiO₂ or WO₃ nanoparticles, 1 mg/mL in deionized water, pH adjusted to ensure stable, opposite surface charge to the preceding layer.

- Substrates: Glass slides, silicon wafers, or quartz.

- Rinsing Solution: Deionized water (18.2 MΩ·cm).

Step-by-Step Procedure:

- Substrate Pretreatment: Clean substrates in piranha solution (3:1 v/v Hâ‚‚SOâ‚„:Hâ‚‚Oâ‚‚) CAUTION: Highly corrosive or via oxygen plasma treatment to create a hydrophilic, negatively charged surface.

- Layer Deposition Cycle: a. Immerse the substrate in the cationic PAH solution for 10-20 minutes to adsorb a positively charged layer. b. Rinse by immersing in three successive beakers of deionized water for 1-2 minutes each to remove loosely adsorbed molecules. c. Gently dry the substrate under a stream of nitrogen gas. d. Immerse the substrate in the anionic PSS solution (or anionic nanoparticle suspension) for 10-20 minutes. e. Repeat the rinsing and drying steps (b and c).

- Film Growth: Repeat Step 2 until the desired number of bilayers (e.g., 10-50) is achieved. The film thickness can be monitored by spectroscopic ellipsometry or UV-Vis absorption after each cycle.

- Post-Assembly Processing: Anneal the final film at a moderate temperature (e.g., 300°C) to enhance mechanical stability and interlayer diffusion, if compatible with the building blocks.

Diagram 1: Electrostatic LbL assembly workflow. NP: Nanoparticle.

Protocol: Hydrogen-Bonding Driven LbL Assembly of HOFs

Hydrogen-Bonded Organic Frameworks (HOFs) represent an emerging class of photocatalysts where assembly is directed by specific hydrogen-bonding interactions [11].

Research Reagent Solutions:

- Donor Molecule Solution: Tetrathiafulvalene tetracarboxylic acid (TTF), 1 mM in a suitable solvent (e.g., DMF).

- Acceptor Molecule Solution: 4,4’-bipyridine (Bpy), 1 mM in a suitable solvent (e.g., DMF).

- Solvent System: A carefully selected mixture (e.g., DMF/acetonitrile) to promote slow crystallization and strong H-bond formation.

Step-by-Step Procedure:

- Solution Preparation: Prepare separate solutions of the electron-donor (TTF) and electron-acceptor (Bpy) building blocks.

- Framework Assembly: Slowly combine the donor and acceptor solutions in a vial. Alternatively, use a slow diffusion method by layering one solution on top of the other.

- Crystallization: Allow the mixture to stand undisturbed at room temperature or a controlled temperature for 12-72 hours to facilitate the formation of crystalline HOFs via O–H⋯O and O–H⋯N hydrogen bonds.

- Product Isolation: Collect the resulting crystalline powder by filtration or centrifugation.

- Activation: Wash the crystals with a volatile solvent (e.g., acetone) and activate under vacuum to remove guest molecules from the pores.

Protocol: Fabrication of LbL Nanotubes via Templated Synthesis

This protocol describes the creation of one-dimensional photocatalytic nanotubes by performing LbL assembly within the nanopores of a membrane template [14].

Research Reagent Solutions:

- Polyelectrolyte Solutions: PAH and PSS, 1-2 mg/mL in 0.5 M NaCl.

- Nanoporous Template: Anodic Aluminum Oxide (AAO) or Track-Etched Polycarbonate (TEPC) membrane (pore diameter 100-400 nm).

- Etching Solution: For AAO: 1M NaOH or aqueous phosphoric acid. For TEPC: Dichloromethane.

Step-by-Step Procedure:

- Template Preparation: Secure the AAO or TEPC membrane in a filtration apparatus.

- Internal Coating: a. Inject the cationic PAH solution through the membrane pores under gentle pressure or vacuum, allowing 10-15 minutes for adsorption. b. Rinse by flushing with deionized water. c. Inject the anionic PSS solution through the membrane, followed by rinsing.

- Bilayer Repetition: Repeat Step 2 until the desired number of bilayers is deposited on the pore walls.

- Nanotube Release: Dissolve the template membrane to liberate the free-standing LbL nanotubes. For AAO, use NaOH; for TEPC, use dichloromethane.

- Purification: Centrifuge and wash the harvested nanotubes repeatedly with deionized water.

The Scientist's Toolkit: Essential Research Reagents

Table 2: Key Reagents for LbL Photocatalyst Fabrication

| Reagent / Material | Function / Role | Example Application |

|---|---|---|

| Poly(allylamine hydrochloride) (PAH) | Cationic polyelectrolyte; provides positive charges for electrostatic assembly [14]. | Building block for multilayer films with PSS [9] [14]. |

| Poly(sodium 4-styrenesulfonate) (PSS) | Anionic polyelectrolyte; provides negative charges for electrostatic assembly [14]. | Building block for multilayer films with PAH [9] [14]. |

| Anodic Aluminum Oxide (AAO) Membrane | Hard nanoporous template with cylindrical pores [14]. | Sacrificial template for synthesizing LbL nanotubes [14]. |

| Tetrathiafulvalene tetracarboxylic acid (TTF) | Electron-donor building block with carboxylic acid groups [11]. | Construction of donor-acceptor HOFs for Hâ‚‚Oâ‚‚ photosynthesis [11]. |

| 4,4'-bipyridine (Bpy) | Electron-acceptor building block with pyridyl nitrogen atoms [11]. | Construction of donor-acceptor HOFs with TTF via H-bonding [11]. |

| Titania (TiOâ‚‚) Nanoparticles | Semiconducting photocatalyst material [9]. | Incorporated into LbL films as an active component for pollutant degradation [9]. |

| PhTD3 | PhTD3 | Chemical Reagent |

| MB-21 | MB-21 Research Compound|Supplier | MB-21 is a high-purity research reagent. This product is For Research Use Only. Not for human or veterinary diagnostic or therapeutic use. |

Application in Photocatalysis: A Case Study

The power of interaction-driven LbL assembly is exemplified by the construction of a donor-acceptor Hydrogen-Bonded Organic Framework (HOF) for the overall photosynthesis of hydrogen peroxide (Hâ‚‚Oâ‚‚) [11].

System: TTF-Bpy-HOF, assembled from TTF (donor) and Bpy (acceptor) units via O–H⋯O and O–H⋯N hydrogen bonds, with additional stabilization from π-π stacking interactions [11].

Performance: The TTF-Bpy-HOF achieved an Hâ‚‚Oâ‚‚ production rate of 681.2 μmol gâ»Â¹ hâ»Â¹ under visible light without sacrificial agents. This was over 9 times higher than the reference HOF (TTF-HOF) without the designed donor-acceptor structure [11].

Mechanistic Insight: The strategic use of hydrogen bonding to create a donor-acceptor structure within the HOF led to accelerated charge separation and transfer, while the π-π stacking provided pathways for electron conduction. This synergistic effect, enabled by specific non-covalent interactions, resulted in dramatically enhanced photocatalytic efficiency [11].

Diagram 2: HOF photocatalyst mechanism. D-A: Donor-Acceptor.

Layer-by-layer (LbL) self-assembly has emerged as a foundational technique in materials science, enabling the precise fabrication of stratified functional nanomaterials. This approach, whose modern conceptualization is often traced to the pioneering work of Iler in the 1960s, has evolved into a sophisticated toolkit for constructing complex heterostructures with atomic-level precision. Within the specific domain of photocatalyst fabrication, LbL self-assembly provides an unparalleled methodology for engineering interfaces that facilitate critical processes such as charge separation and vectorial electron transfer. By judiciously combining building blocks with complementary properties—such as varying band structures, surface functionalities, and dimensionalities—researchers can fabricate hybrid photocatalysts whose performance surpasses the sum of their constituent parts. This application note details the progression from foundational principles to contemporary experimental protocols, providing researchers with the practical frameworks required to leverage LbL self-assembly for advanced photocatalytic applications, including water splitting, CO2 reduction, and wastewater treatment [15] [16].

The Evolution of LbL Concepts and Materials

The historical trajectory of LbL self-assembly is characterized by a strategic expansion of its constituent building blocks and a refinement of its driving forces. Initially demonstrated with simple charged species, the methodology now encompasses a vast library of nanoscale components. The table below summarizes the evolution of key material classes used in LbL-assembled photocatalysts.

Table 1: Historical Evolution of Material Classes in LbL Self-Assembly for Photocatalysis

| Time Period | Material Class | Example Materials | Key Advancement | Impact on Photocatalytic Performance |

|---|---|---|---|---|

| Early/Foundational | Polyelectrolytes | Poly(ethyleneimine) (PEI), PDAC | Introduction of electrostatic driving force for LbL. | Enabled basic stratified structure formation, though often with insulating layers that limited charge transfer [17]. |

| Modern Expansion | 2D Inorganic Nanosheets | Perovskite Niobates (HPbâ‚‚Nb₃Oâ‚â‚€), Layered Double Hydroxides (Zn/Cr-LDH) | Utilization of intrinsically charged, semiconducting 2D flakes. | Created intimate, face-to-face heterojunctions; enhanced charge separation via internal electric fields [15]. |

| Modern Expansion | Small Molecule Pillars | Tris(2-aminoethyl)amine (TAEA) | Replaced bulky polymers with minimal molecular pillars. | Maximized interlayer electronic conductivity (e.g., 7.3 × 10â´ S mâ»Â¹ for MXene/TAEA) and provided sub-nanometer control over interlayer spacing [17]. |

| Cutting-Edge | Inorganic Perovskite QDs | CsPbBr₃ Quantum Dots (QDs) | Integration of high-efficiency light harvesters onto 2D substrates. | Combined superior optoelectronic properties of QDs with the charge-stabilizing function of 2D scaffolds for reactions like CO₂ reduction [18]. |

The most significant advancements have stemmed from the shift towards using 2D nanomaterials and small molecule linkers. For instance, the assembly of oppositely charged perovskite niobate (HPbâ‚‚Nb₃Oâ‚â‚€) and Zn/Cr-LDH nanosheets creates a heterolayered structure where the internal electric field at the interface drastically improves the separation of photo-generated electron-hole pairs, leading to a substantial enhancement in photocatalytic oxygen generation [15]. Similarly, replacing insulating polymers with a small molecule like TAEA for pillaring MXene (Ti₃Câ‚‚Tâ‚“) layers results in a highly ordered, conductive architecture ideal for supercapacitors and related electrochemical applications [17].

Experimental Protocols for Key LbL Systems

Protocol 1: LbL Assembly of 2D Perovskite Niobate and LDH for Oxygen Evolution

This protocol describes the construction of a heterolayered Zn/Cr-LDH/HPbâ‚‚Nb₃Oâ‚â‚€ composite photocatalyst for enhanced oxygen generation under visible light [15].

1. Synthesis of Building Blocks:

- HPbâ‚‚Nb₃Oâ‚â‚€ (PNO) Nanosheets:

- Precursor Synthesis: Begin by synthesizing RbPbâ‚‚Nb₃Oâ‚â‚€ via solid-state reaction from Rbâ‚‚CO₃, PbO, and Nbâ‚‚Oâ‚…. Calcinate the mixture at 1150°C for 6 hours.

- Proton Exchange: Convert RbPbâ‚‚Nb₃Oâ‚â‚€ to HPbâ‚‚Nb₃Oâ‚â‚€ by stirring in 6 M HNO₃ for 72 hours, with acid refreshed every 24 hours.

- Exfoliation: Stir the protonated compound in a 20% tetrabutylammonium hydroxide (TBAOH) solution for 7 days. Centrifuge the resulting colloidal suspension at 10,000 rpm to obtain a stable suspension of negatively charged PNO nanosheets.

- Zn/Cr-LDH Nanosheets:

- Bulk LDH Synthesis: Precipitate Zn/Cr-LDH from an aqueous solution of Zn(NO₃)₂·6H₂O and Cr(NO₃)₃·9H₂O (Zn/Cr molar ratio = 2:1) by adjusting the pH to 9.5 with NaOH. Age the slurry at 60°C for 18 hours.

- Exfoliation: Vigorously shake the bulk LDH in formamide (20 mg/mL) for 5 minutes to obtain a colloidal suspension of positively charged LDH nanosheets.

2. Layer-by-Layer Self-Assembly:

- Mix the as-prepared aqueous suspensions of positively charged LDH nanosheets and negatively charged PNO nanosheets.

- Allow the electrostatic self-assembly to proceed spontaneously, which will be visually confirmed by the formation of sediments.

- Collect the composite product (labeled LDH-PNO) via centrifugation, wash thoroughly with deionized water and ethanol, and dry in a vacuum oven.

3. Photocatalytic Oxygen Generation Test:

- Disperse 50 mg of the LDH-PNO photocatalyst in an aqueous silver nitrate (AgNO₃, 0.01 M) solution in a top-irradiation photoreactor. AgNO₃ acts as a sacrificial electron acceptor.

- Evacuate the system to remove air and illuminate with a 300 W Xe lamp equipped with a UV-cutoff filter (λ > 420 nm) to provide visible light.

- Quantify the evolved oxygen gas using an online gas chromatograph equipped with a thermal conductivity detector (TCD).

Protocol 2: Electrostatic Self-Assembly of CsPbBr₃ QDs on 2D Bi₂O₂CO₃ for CO₂ Reduction

This protocol outlines the creation of a quantum dot/2D composite for visible-light-driven photocatalytic COâ‚‚ reduction [18].

1. Synthesis of 2D Bi₂O₂CO₃ (BOC) Petals on a Substrate:

- Clean a glass substrate (e.g., 1 cm²) sequentially with acetone, isopropanol, and deionized water, then dry with N₂ gas.

- Thermally evaporate a 30-nm thick Bi film onto the substrate at a rate of 0.5 Ã… sâ»Â¹ under high vacuum.

- Immerse the Bi-film-coated substrate into a CO₂-saturated 0.1 M KHCO₃ solution for 30 minutes. A spontaneous redox reaction will convert the Bi film into petal-like BOC structures.

- Rinse the sample with deionized water and dry with Nâ‚‚ gas.

2. Synthesis and Purification of CsPbBr₃ (CPB) Quantum Dots (QDs):

- Cesium Oleate Precursor: Mix 0.814 g Cs₂CO₃, 2.5 mL oleic acid, and 40 mL octadecene (ODE). Stir at 150°C for 1 hour until fully dissolved.

- QD Synthesis: In a separate 3-neck flask, heat 2 mL oleylamine (OLAM) to 100°C. Add 20 mL ODE and 0.276 g PbBr₂. Stir and heat to 120°C until the PbBr₂ dissolves.

- Inject 2 mL OLAM and 2 mL oleic acid into the PbBr₂ solution and stir for 5 minutes. Then, heat the mixture to 140°C and swiftly inject 1.6 mL of the prepared cesium oleate solution.

- After 5 seconds, immediately cool the reaction mixture in an ice bath to terminate the reaction.

- Purification: Add methyl acetate to the crude QD solution (1:1 volume ratio) and centrifuge at 1350 rpm for 5 minutes. Discard the supernatant, re-disperse the pellet in a hexane/methyl acetate mixture, and repeat centrifugation. Finally, disperse the purified QD pellet in octane.

3. Electrostatic Self-Assembly of CPB QD/BOC Heterojunction:

- Confirm the opposite surface charges of the BOC petals and CPB QDs using zeta potential measurements in isopropanol.

- Drop-cast the suspension of negatively charged CPB QDs onto the positively charged BOC petal substrate.

- The electrostatic interaction will drive the self-assembly, resulting in a uniform coating of CPB QDs on the BOC petals.

4. Photocatalytic COâ‚‚ Reduction Reaction (COâ‚‚ RR):

- Place the CPB QD/BOC monolithic photocatalyst in a custom-designed reactor purged with COâ‚‚.

- Irradiate the sample under visible light (e.g., using a Xe lamp with a 420 nm cutoff filter).

- Analyze the gas products periodically using a gas chromatograph to quantify the production rate of CO (and other products like CHâ‚„ if applicable).

The Scientist's Toolkit: Essential Research Reagent Solutions

The successful implementation of LbL self-assembly relies on a suite of key reagents and materials. The following table itemizes critical components and their functions in the featured protocols.

Table 2: Key Research Reagent Solutions for LbL Photocatalyst Fabrication

| Reagent/Material | Function in LbL Self-Assembly | Exemplary Use Case |

|---|---|---|

| Tetrabutylammonium Hydroxide (TBAOH) | A bulky intercalant and exfoliating agent that separates layers of layered perovskites into colloidal nanosheets. | Exfoliation of HPbâ‚‚Nb₃Oâ‚â‚€ to produce negatively charged perovskite niobate nanosheets [15]. |

| Formamide | A polar solvent that facilitates the exfoliation of Layered Double Hydroxides (LDHs) into positively charged 2D nanoplatelets. | Production of a stable suspension of Zn/Cr-LDH nanosheets [15]. |

| Tris(2-aminoethyl)amine (TAEA) | A small, multi-amino molecule that acts as a molecular pillar, creating a defined, conductive gap between 2D nanosheets via electrostatic interactions. | Fabrication of highly conductive (MXene/TAEA)â‚™ pillared multilayers for energy storage [17]. |

| Oleylamine (OLAM) & Oleic Acid (OA) | Surface capping ligands that control the growth, stability, and dispersion of quantum dots during synthesis and subsequent processing. | Synthesis and stabilization of CsPbBr₃ QDs for electrostatic assembly onto BOC petals [18]. |

| Silver Nitrate (AgNO₃) | A sacrificial electron acceptor (hole scavenger) used in photocatalytic tests to validate oxygen evolution activity by consuming photogenerated holes. | Photocatalytic O₂ generation test with the LDH-PNO composite photocatalyst [15]. |

| KWKLFKKGAVLKVLT | KWKLFKKGAVLKVLT Cationic Antimicrobial Peptide | |

| KWKLFKKAVLKVLTT | CAM Hybrid Antimicrobial Peptide | Research-grade CAM cationic polypeptide (KWKLFKKAVLKVLTT). For antibacterial mechanism studies. For Research Use Only. Not for human consumption. |

Signaling Pathways and Charge Transfer Mechanisms

The enhanced performance of LbL-assembled photocatalysts is fundamentally governed by efficient charge separation and transfer at the heterojunction interfaces. Two primary mechanisms are operative in the systems described.

5.1 Type-II Heterojunction and S-Scheme Mechanism In the CPB QD/BOC system, an S-scheme heterojunction is formed. The internal electric field (E-field) at the interface between the two n-type semiconductors (BOC, acting as the Oxidation Photocatalyst (OP), and CPB QDs, acting as the Reduction Photocatalyst (RP)) drives the recombination of useless electrons in the OP (BOC) with useless holes in the RP (CPB QDs). This leaves the most reductive electrons in the CB of CPB QDs and the most oxidative holes in the VB of BOC, thereby achieving superior charge separation and high redox power for COâ‚‚ reduction [18].

5.2 Electrostatic-Driven Assembly Workflow The fabrication of these advanced materials follows a logical sequence from precursor preparation to functional testing, with electrostatic interactions serving as the central driving force for assembly.

The evolution of layer-by-layer self-assembly from Iler's foundational concepts to today's sophisticated methodologies has fundamentally transformed the design principles for next-generation photocatalysts. By moving from simple polyelectrolytes to high-performance 2D semiconductors and quantum dots, and by replacing insulating spacers with conductive molecular pillars, the field has unlocked unprecedented control over the structural and electronic properties of hybrid materials. The detailed protocols for constructing 2D/2D heterolayers and QD/2D composites, supported by the essential reagent toolkit and clear diagrams of charge transfer mechanisms, provide a robust framework for researchers. As the understanding of interfacial phenomena deepens, LbL self-assembly is poised to remain a cornerstone technique for engineering advanced functional materials with tailored properties for energy and environmental applications.

Layer-by-layer (LbL) self-assembly has emerged as a powerful and versatile technique for fabricating hybrid photocatalysts with tailored properties for energy and environmental applications [19]. This technique involves the sequential adsorption of oppositely charged materials onto a substrate, enabling precise control over film composition, thickness, and nanoarchitecture at the molecular level. The choice of building blocks—including semiconductors, polyelectrolytes, and biomaterials—critically determines the functional properties of the resulting photocatalytic assemblies. These materials are integrated through various driving forces such as electrostatic interactions, hydrogen bonding, and van der Waals forces, which govern the self-assembly process and final material characteristics [20] [21]. This application note provides detailed protocols for the selection and integration of these building blocks, with a specific focus on enhancing photocatalytic performance for applications such as water splitting and pollutant degradation. The methodologies outlined herein are designed to offer researchers reproducible techniques for constructing advanced photocatalytic systems with enhanced charge separation, improved stability, and tailored surface properties.

Research Reagent Solutions: Essential Materials for LbL Photocatalyst Fabrication

Table 1: Key research reagents for LbL assembly of hybrid photocatalysts.

| Reagent Category | Specific Examples | Function in LbL Assembly |

|---|---|---|

| Semiconductor Nanosheets | HPbâ‚‚Nb₃Oâ‚â‚€ nanosheets [15], Zn/Cr-Layered Double Hydroxide (LDH) nanosheets [15], g-C₃Nâ‚„ nanosheets [22] | Provide photocatalytic activity; form heterojunctions for enhanced charge separation; serve as charged building blocks for electrostatic assembly. |

| Polyelectrolytes | Polyethylenimine (PEI) [20], Poly(acrylic acid) (PAA) [20] | Act as polymeric spacers and binders; facilitate electrostatic layering; create porous structures for dye adsorption. |

| Magnetic Components | Fe₃O₄ nanoparticles [22] | Enable magnetic recovery and reuse of photocatalysts; facilitate separation from reaction mixtures. |

| Exfoliation & Dispersion Agents | Tetrabutylammonium hydroxide [15], Formamide [15], Isopropyl alcohol (IPA) [23] | Aid in the exfoliation of layered materials into nanosheets; create stable colloidal suspensions for LbL deposition. |

| Precursor Salts | Zn(NO₃)₂·6H₂O, Cr(NO₃)₃·9H₂O [15], CuSO₄·5H₂O [22], FeCl₂·4H₂O, FeCl₃·6H₂O [22] | Used in the synthesis of semiconductor and magnetic nanoparticle building blocks. |

Quantitative Performance Data for LbL-Assembled Photocatalysts

Table 2: Performance metrics of LbL-assembled photocatalysts and constituent materials.

| Photocatalyst Material | Application | Key Performance Metrics | Reference |

|---|---|---|---|

| Zn/Cr-LDH / HPbâ‚‚Nb₃Oâ‚â‚€ Heterolayer Composite | Photocatalytic Oxygen Generation | Enhanced performance vs. pristine Zn/Cr-LDH; suitable band alignment for charge separation. | [15] |

| g-C₃N₄/Fe₃O₄/CuO Composite | Methylene Blue Degradation | >90% removal within 60 min under UV light; optimal performance at pH = 9; >80% activity retention after 6 cycles. | [22] |

| g-C₃N₄/Fe₃O₄/CuO Composite | Synthesis of 2-amino-4H-benzochromenes | Product yields >89% under mild, neutral conditions. | [22] |

| D@GO-COOH@(PEI/PAA)₈ Core-Shell Composite | Dye Adsorption (MB, RhB) | High surface area and mesoporous structure; adsorption follows pseudo-second-order model. | [20] |

| Electrochemically Exfoliated Graphene (EEG) Film | Transparent Conductive Films | Conductivity: ~1.3 × 10ⵠS/m at 11 nm thickness; 82% transparency with 4.2 kΩ/□ sheet resistance at 6.1 nm. | [23] |

Experimental Protocols for LbL Photocatalyst Fabrication and Testing

Protocol: Fabrication of a Hetero-layered Zn/Cr-LDH/HPbâ‚‚Nb₃Oâ‚â‚€ Photocatalyst

This protocol details the synthesis of a hetero-layered composite photocatalyst for enhanced oxygen evolution via electrostatic self-assembly of 2D semiconductor nanosheets [15].

Materials and Equipment:

- Precursors: Rb₂CO₃ (99.9%), PbO (99.0%), Nb₂O₅ (99.5%), Zn(NO₃)₂·6H₂O (99.0%), Cr(NO₃)₃·9H₂O (99.0%)

- Exfoliation Agents: Tetrabutylammonium hydroxide (10 wt% in water), Formamide (99.5%)

- Equipment: Tube furnace, Muffle furnace, Centrifuge, Ultrasonic bath, Vacuum filtration system

Step-by-Step Procedure:

Synthesis of RbPbâ‚‚Nb₃Oâ‚â‚€ Precursor:

- Solid-state reaction: Combine Rb₂CO₃, PbO, and Nb₂O₅ in stoichiometric proportions.

- Calcinate the mixture at 1150°C for 30 minutes in a muffle furnace.

- Grind the product into a fine powder after cooling.

Preparation of HPbâ‚‚Nb₃Oâ‚â‚€ (PNO):

- Proton exchange: Stir 5 g of RbPbâ‚‚Nb₃Oâ‚â‚€ powder in 200 mL of 6 M HNO₃ for 72 hours at room temperature.

- Collect the resulting solid via vacuum filtration and wash thoroughly with deionized water.

- Dry the final product (HPbâ‚‚Nb₃Oâ‚â‚€) at 80°C for 12 hours.

Exfoliation of HPbâ‚‚Nb₃Oâ‚â‚€ into Nanosheets:

- Add 1 g of HPbâ‚‚Nb₃Oâ‚â‚€ powder to 200 mL of tetrabutylammonium hydroxide solution (0.2 mol/L).

- Vigorously stir this suspension for 7 days at room temperature to achieve exfoliation.

- Centrifuge the resulting colloidal suspension at 3000 rpm for 15 minutes to remove any unexfolated bulk material.

- The final product is a stable, opalescent suspension of negatively charged PNO nanosheets in the supernatant.

Synthesis and Exfoliation of Zn/Cr-LDH Nanosheets:

- Co-precipitation: Dissolve Zn(NO₃)₂·6Hâ‚‚O and Cr(NO₃)₃·9Hâ‚‚O (Zn²âº/Cr³⺠molar ratio = 2:1) in 100 mL deionized water.

- Precipitate the LDH by adding NaOH solution dropwise under constant stirring, maintaining the pH at 9.0.

- Age the resulting slurry at 80°C for 18 hours.

- Collect the precipitate by filtration, wash, and dry.

- Exfoliation: Vigorously shake 0.5 g of the Zn/Cr-LDH powder in 500 mL formamide for 30 minutes to obtain a colloidal suspension of positively charged LDH nanosheets.

Electrostatic Layer-by-Layer Self-Assembly:

- Separately disperse the as-prepared PNO and LDH nanosheet suspensions in formamide to form transparent suspensions.

- Combine the two suspensions under gentle stirring. The spontaneous formation of sediment indicates successful electrostatic self-assembly.

- Continue stirring for 2 hours to ensure complete restacking.

- Collect the final hetero-layered composite (denoted as LDH-PNO) by filtration, wash with methanol, and dry at 80°C for 12 hours.

Protocol: One-Pot Synthesis of g-C₃N₄/Fe₃O₄/CuO Magnetic Photocatalyst

This protocol describes a solvothermal method to create a magnetically recoverable ternary photocatalyst for combined pollutant degradation and organic synthesis [22].

Materials and Equipment:

- Precursors: Melamine, FeCl₂·4H₂O, FeCl₃·6H₂O, CuSO₄·5H₂O

- Reagents: NaOH, Ammonia solution (25%), Chloroacetic acid

- Equipment: Porcelain crucible, Autoclave, Oven, Heating stirrer, Ultrasonic probe

Step-by-Step Procedure:

Synthesis of g-C₃N₄ Nanosheets:

- Place 10 g of melamine in a covered porcelain crucible.

- Heat in a muffle furnace at 550°C for 4 hours to form bulk g-C₃N₆ via thermal polymerization.

- Allow the resulting yellow solid to cool to room temperature.

- Convert the bulk material into ultrathin nanosheets by liquid exfoliation (sonication in water or isopropyl alcohol for several hours).

One-Pot Solvothermal Synthesis of the Composite:

- In-situ formation of Fe₃O₄: Dissolve appropriate amounts of FeCl₂·4H₂O and FeCl₃·6H₂O (molar ratio ~1:2) in 30 mL deionized water each. Combine the two solutions and stir for 15 minutes. Add 20-25 mL of 25% ammonia solution dropwise to precipitate black Fe₃O₄ nanoparticles. Wash the precipitate to neutral pH using magnetic separation.

- Incorporation of CuO: Add a precursor solution of CuSO₄·5H₂O to the mixture.

- Add the exfoliated g-C₃N₄ nanosheets to the above mixture containing Fe₃O₄ and CuO precursors.

- Transfer the entire suspension into a Teflon-lined stainless-steel autoclave.

- Heat the autoclave to a temperature between 105-150°C and maintain for 12 hours.

- After cooling, collect the solid product by filtration or magnetic separation.

- Wash the final g-C₃N₄/Fe₃O₄/CuO composite sequentially with ethanol and deionized water, and dry at 80°C for 12 hours.

Protocol: Performance Evaluation - Photocatalytic Dye Degradation

This standard protocol is used to assess the efficiency of synthesized photocatalysts in degrading organic pollutants like methylene blue (MB) [22].

Materials and Equipment:

- Target Pollutant: Methylene Blue (MB) dye solution (e.g., 10 mg/L)

- Light Source: UV or visible light lamp (e.g., 300 W Xe lamp)

- Analytical Instrument: UV-Vis spectrophotometer

Step-by-Step Procedure:

Reaction Setup:

- Disperse 50 mg of the photocatalyst in 100 mL of the MB solution.

- Before illumination, stir the suspension in the dark for 60 minutes to establish an adsorption-desorption equilibrium.

Photocatalytic Reaction:

- Illuminate the reactor with the light source under continuous stirring.

- Maintain constant temperature (e.g., 25°C) using a cooling water circulation system.

Sampling and Analysis:

- At regular time intervals (e.g., 0, 10, 20, 30, 45, 60 min), withdraw 3-4 mL aliquots of the suspension.

- Immediately centrifuge the samples or use a 0.45 μm syringe filter to remove the catalyst particles.

- Analyze the clear filtrate using a UV-Vis spectrophotometer by measuring the absorbance of MB at its characteristic wavelength (λₘâ‚â‚“ ≈ 664 nm).

- Calculate the degradation efficiency (%) using the formula:

(1 - C/C₀) × 100%, where C₀ is the initial concentration after dark adsorption and C is the concentration at time t.

Reusability Testing:

- After each degradation cycle, recover the catalyst by magnetic separation (for magnetic composites) or centrifugation.

- Wash the recovered catalyst with water and ethanol, then dry.

- Repeat the degradation experiment under identical conditions to evaluate the catalyst's stability and reusability over multiple cycles.

Workflow Visualization: LbL Fabrication and Photocatalytic Testing

LbL Photocatalyst Fabrication and Application Workflow

Electrostatic LbL Assembly Mechanism

Layer-by-Layer (LbL) self-assembly has emerged as a powerful methodological platform for the rational design and fabrication of hybrid photocatalysts. This technique, which involves the sequential deposition of oppositely charged materials to build up nanoscale thin films, provides researchers with unprecedented control over composition, interface, and structure at the molecular level [24] [1]. Within the broader context of materials nanoarchitectonics—a paradigm that emphasizes the precise organization of nanoscale building blocks into functional architectures—LbL assembly stands out for its unique combination of simplicity, versatility, and scalability [24]. These intrinsic advantages make it particularly valuable for constructing advanced photocatalytic systems for environmental remediation and energy conversion applications, where control over charge separation and surface reactivity is paramount [1] [25].

Core Advantages of LbL Assembly

Simplicity and Operational Ease

The LbL technique fundamentally operates through alternating deposition of interacting species, typically driven by electrostatic interactions, making it conceptually straightforward and experimentally accessible [1] [26]. Unlike many bottom-up nanofabrication approaches that require specialized equipment or stringent conditions, LbL assembly can be implemented using basic laboratory apparatus.

Key aspects contributing to its simplicity include:

- Minimal equipment requirements: Basic immersion, spraying, or spinning setups suffice for most applications [27]

- Ambient operation conditions: Typically performed at room temperature and pressure without needing controlled atmospheres [1]

- Straightforward procedural workflow: Sequential dipping/rinsing cycles that are easily standardized and automated [26]

This operational simplicity significantly lowers the barrier to entry for researchers exploring hybrid photocatalyst development compared to techniques like chemical vapor deposition or molecular beam epitaxy that demand sophisticated infrastructure [1].

Exceptional Versatility and Material Compatibility

LbL assembly demonstrates remarkable versatility in terms of applicable materials, substrate geometries, and functional integration capabilities. The technique accommodates an extensive range of building blocks including polymers, nanoparticles, biomolecules, and two-dimensional materials [24] [1].

Table 1: Material Diversity Compatible with LbL Assembly for Photocatalysis

| Material Category | Specific Examples | Functional Role in Photocatalysts |

|---|---|---|

| Polyelectrolytes | Chitosan, alginate, hyaluronic acid, poly(acrylic acid) | Structural matrix, controlled release, stability enhancement [27] |

| Inorganic Nanomaterials | TiOâ‚‚, ZnO, MoSâ‚‚, MXenes | Light absorption, charge generation, catalytic activity [24] [28] |

| Functional Organics | Porphyrins (TCPP), conjugated polymers | Visible light harvesting, sensitization, charge transport [28] |

| Hybrid Systems | MOF-based composites, organic-inorganic heterostructures | Synergistic effects, multifunctionality, tailored interfaces [29] |

The method successfully integrates materials with diverse compositions, sizes, and properties into organized architectures, enabling the creation of precisely engineered photocatalysts with tailored light absorption, charge separation, and surface reactivity [24] [1] [28].

Scalability and Manufacturing Potential

LbL assembly offers multiple pathways for scaling from laboratory demonstrations to practically viable applications. The technique's adaptability to different deposition modes enables researchers to select the most appropriate scaling strategy based on their specific application requirements [27].

Table 2: Scaling Potential of Different LbL Implementation Modalities

| Assembly Method | Throughput Potential | Applicable Substrate Types | Limitations |

|---|---|---|---|

| Immersion/Dipping | Moderate | Complex geometries, high surface area structures | Time-consuming for many layers [27] |

| Spray-Assisted | High | Large flat surfaces, roll-to-roll compatible | Potential material loss, uniformity challenges [27] |

| Microfluidic-Assisted | Low to moderate | Microscale substrates, precise patterning | Complex setup, limited to small areas [27] |

Spray-assisted LbL in particular has demonstrated promising scalability for large-area coatings while maintaining reasonable deposition speeds and material utilization efficiency [27]. This manufacturing potential positions LbL as a viable route for producing photocatalyst coatings on practical substrates including electrodes, membranes, and particulate systems.

Comparative Advantage Over Alternative Techniques

When evaluated against other bottom-up nanofabrication approaches, LbL assembly demonstrates distinct advantages that explain its growing adoption in photocatalyst development.

Table 3: LbL Versus Alternative Nanofabrication Techniques

| Technique | Key Advantages | Limitations | Comparison to LbL |

|---|---|---|---|

| Langmuir-Blodgett (LB) | Highly ordered monolayers, precise thickness control | Limited substrate choice, requires amphiphilic molecules, difficult scaling [1] | LbL offers superior substrate flexibility and scalability [1] |

| Self-Assembled Monolayers (SAMs) | Simple formation, strong substrate bonding | Mostly single-layer, limited material options [1] | LbL enables multilayer architectures with diverse components [1] |

| Chemical Vapor Deposition (CVD) | High purity films, excellent conformality | High temperature, vacuum requirements, limited material compatibility [1] | LbL operates under mild conditions with broader material range [1] |

| Hydrothermal/Solvothermal | Crystalline products, morphology control | Batch processing, energy intensive, limited interface control [1] | LbL provides superior interfacial precision and sequential integration [1] |

The comparative analysis reveals that LbL assembly occupies a unique position in the materials engineering toolbox, offering a balance of precision, versatility, and practical feasibility that is difficult to achieve with competing techniques [1]. This advantage is particularly valuable for hybrid photocatalyst systems where multiple functional components must be integrated with controlled interfacial properties.

Experimental Protocol: Fabrication of MoSâ‚‚/TCPP Hybrid Photocatalyst via LbL Assembly

Research Reagent Solutions

Table 4: Essential Materials for MoSâ‚‚/TCPP Hybrid Photocatalyst Fabrication

| Reagent/Material | Specifications | Functional Role |

|---|---|---|

| Ammonium Molybdate Tetrahydrate | (NH₄)₆Mo₇O₂₄·4H₂O, 99% purity (Sigma-Aldrich) | Molybdenum source for MoS₂ synthesis [28] |

| Thiourea | CHâ‚„Nâ‚‚S, 99% purity (Sigma-Aldrich) | Sulfur source for MoSâ‚‚ synthesis [28] |

| TCPP | Tetrakis(4-carboxyphenyl)porphyrin (Macklin) | Organic photosensitizer, visible light harvester [28] |

| Absolute Ethanol | ≥99.8%, AR grade (Fisher) | Solvent for TCPP solutions [28] |

| Hydroxylammonium chloride | NH₂OH·Cl, >98.5% (Sigma-Aldrich) | Reducing agent for synthetic modifications [28] |

| Substrates | Silicon wafers, FTO glass, quartz slides | Support materials for LbL film deposition [28] |

Step-by-Step Experimental Procedure

Part A: Hydrothermal Synthesis of MoSâ‚‚ Nanoflowers

- Precursor Solution Preparation: Dissolve 1.0 mmol ammonium molybdate tetrahydrate and 30 mmol thiourea in 70 mL deionized water under magnetic stirring for 30 minutes until complete dissolution [28].

- Hydrothermal Reaction: Transfer the clear solution to a 100 mL Teflon-lined stainless steel autoclave. Seal and maintain at 200°C for 24 hours in a forced convection oven [28].

- Product Recovery: After natural cooling to room temperature, collect the black precipitate by centrifugation at 8,000 rpm for 10 minutes.

- Washing and Drying: Wash sequentially with deionized water and absolute ethanol three times each, then dry in a vacuum oven at 60°C for 12 hours [28].

- Thermal Treatment: Anneal the obtained MoS₂ powder in a tube furnace at 350°C for 2 hours under continuous Ar gas flow (50 sccm) to enhance crystallinity [28].

Part B: LbL Assembly of MoSâ‚‚/TCPP Hybrid Photocatalyst

- Stock Solution Preparation:

- Prepare MoSâ‚‚ dispersion (0.5 mg/mL) in deionized water with 30 minutes ultrasonication

- Prepare TCPP solution (0.25 mg/mL) in absolute ethanol [28]

- Substrate Pretreatment:

- Clean substrates (e.g., FTO glass, silicon wafers) with oxygen plasma for 5 minutes to enhance surface hydrophilicity

- Alternatively, use piranha solution (3:1 Hâ‚‚SOâ‚„:Hâ‚‚Oâ‚‚) treatment for 30 minutes (CAUTION: extremely corrosive)

- Spray-Assisted LbL Assembly [27]:

- Step 1: Spray MoSâ‚‚ dispersion for 10 seconds using an airbrush system (15 psi Nâ‚‚ pressure, 15 cm nozzle-to-substrate distance)

- Step 2: Rinse with deionized water spray for 5 seconds to remove loosely adsorbed material

- Step 3: Dry with gentle Nâ‚‚ flow for 30 seconds

- Step 4: Spray TCPP solution for 10 seconds using the same parameters

- Step 5: Rinse with ethanol spray for 5 seconds

- Step 6: Dry with gentle Nâ‚‚ flow for 30 seconds

- Cycle Repetition: Repeat steps 1-6 for 10-20 cycles to achieve the desired film thickness and composition [28].

- Final Processing: Anneal the assembled films at 150°C for 1 hour under Ar atmosphere to enhance interfacial contact and stability [28].

Characterization and Performance Evaluation

Morphological Analysis:

- Field-emission scanning electron microscopy (FE-SEM) to verify hierarchical flower-like MoSâ‚‚ nanostructures and hybrid film morphology [28]

- Transmission electron microscopy (TEM) for detailed interface analysis between MoSâ‚‚ and TCPP

Structural and Chemical Characterization:

- X-ray diffraction (XRD) to confirm MoSâ‚‚ crystallinity and phase purity [28]

- Fourier-transform infrared spectroscopy (FT-IR) to verify TCPP incorporation and identify interaction mechanisms

- Raman spectroscopy to assess MoSâ‚‚ layer number and quality

Optical and Electronic Properties:

- UV-Vis diffuse reflectance spectroscopy (DRS) to determine band gap energies and light absorption characteristics [28]

- Photoluminescence spectroscopy to evaluate charge separation efficiency

Photocatalytic Performance Testing:

- Evaluate Rhodamine B (RhB) degradation under simulated sunlight (300 W Xe lamp, AM 1.5G filter) [28]

- Standard protocol: 10 mg photocatalyst in 50 mL RhB solution (10 mg/L), magnetic stirring in the dark for 30 minutes to establish adsorption-desorption equilibrium before illumination [28]

- Monitor degradation by measuring RhB absorption peak (554 nm) at 15-minute intervals using UV-Vis spectroscopy [28]

Diagram Title: LbL Assembly Workflow and Interface Engineering

Critical Parameters for Optimization

Successful implementation of LbL assembly for photocatalytic applications requires careful optimization of several interdependent parameters:

5.1 Solution Conditions

- pH control: Critical for modulating charge density of weak polyelectrolytes and influencing film growth mechanism [26] [27]

- Ionic strength: Salt concentration affects chain conformation and interpenetration, influencing film porosity and thickness [26]

- Concentration optimization: Typically 0.1-1.0 mg/mL for nanomaterials; balance between deposition efficiency and material utilization [27]

5.2 Processing Parameters

- Deposition time: Varies by method (5-20 minutes for immersion; seconds for spraying) [27]

- Rinsing protocol: Essential for removing loosely bound material; affects film quality and stability [26]

- Drying conditions: Influences layer reorganization and interdiffusion; gentle Nâ‚‚ flow recommended [27]

5.3 Material-Specific Considerations

- Charge density matching: Between successive layers for continuous film growth [26] [27]

- Solvent compatibility: Particularly important for hybrid organic-inorganic systems [28]

- Post-assembly treatments: Thermal/chemical processing to enhance stability and interfacial contact [28]

The simplicity, versatility, and scalability of LbL assembly position it as an indispensable tool in the nanoarchitectonics toolbox for hybrid photocatalyst development. As research advances, integration of LbL with emerging methodologies such as artificial intelligence-guided materials design [24] and high-throughput robotic synthesis [27] promises to accelerate the discovery and optimization of next-generation photocatalytic systems. The protocol detailed herein for MoSâ‚‚/TCPP hybrid structures provides a adaptable template that can be extended to diverse material combinations including MXenes, metal-organic frameworks, and perovskite nanocrystals [29] [28], enabling researchers to harness the full potential of LbL self-assembly for addressing pressing challenges in solar energy conversion and environmental remediation.

Fabrication Techniques and Real-World Applications in Catalysis and Biomedicine

The Layer-by-Layer (LbL) self-assembly technique represents a versatile bottom-up approach for fabricating ultrathin, functional films with precise control over composition and thickness at the nanoscale. This method involves the sequential adsorption of complementary multivalent species onto a substrate, driven primarily by electrostatic interactions, though non-electrostatic interactions including hydrogen bonding and π-π stacking are also employed [9]. The significance of LbL assembly in hybrid photocatalyst fabrication stems from its ability to integrate diverse nanomaterials—such as metal oxide nanoparticles, conjugated polymers, and carbon-based materials—into organized multilayered architectures. These structures enhance photocatalytic performance by improving charge separation, increasing active surface area, and facilitating the degradation of environmental pollutants, including pharmaceuticals and industrial dyes [9] [30].

Within the broader context of photocatalytic research, LbL fabrication addresses a critical challenge: the immobilization of nanostructured photocatalysts to prevent nanotoxicity and agglomeration while enabling catalyst recovery and reuse [9]. As photocatalytic systems advance, the LbL technique provides a methodological framework for constructing sophisticated heterojunctions and Z-scheme configurations, which are essential for efficient solar energy conversion and environmental remediation [30]. The following sections detail the core LbL fabrication methods—Dip-Coating, Spin-Assisted, and Spray-LbL—highlighting their protocols, applications, and quantitative performance in hybrid photocatalyst development.

Comparative Analysis of LbL Fabrication Methods

The table below summarizes the key characteristics, advantages, and limitations of the three core LbL fabrication methods, providing a structured comparison for researchers.

Table 1: Comparative Analysis of Core LbL Fabrication Methods

| Feature | Dip-Assisted LbL | Spin-Assisted LbL (SSLbL) | Spray-Assisted LbL (SLbL) |

|---|---|---|---|

| Fundamental Principle | Sequential substrate immersion in precursor solutions with rinsing between cycles [9]. | Rapid deposition utilizing centrifugal force to spread material; rotation speed controls thickness [9] [31]. | Aerosol spraying of polyelectrolyte/nanoparticle solutions onto the substrate surface [9] [32]. |

| Typical Assembly Time | 25 minutes per bilayer (for polyelectrolyte systems) [32]. | Less than 1 second per layer [9]. | 60 seconds per layer can achieve quality comparable to 25-minute dip-coating [32]. |

| Film Thickness Control | Controlled by number of bilayers, ionic strength, pH, and concentration [9]. | Highly controlled by rotational speed and solution viscosity [9] [31]. | Controlled by number of bilayers, spray time, and solution concentration [32]. |

| Relative Scaling Potential | Moderate, limited by long processing times and large solution volumes [9]. | High for flat substrates; suitable for automation [9]. | Very high; easily automated and adapted for large or irregular surfaces [9] [32]. |

| Key Advantages | Simplicity, applicability to complex geometries, high film stability [9]. | Extreme speed, uniform coatings, reduced material usage [9]. | Rapid processing, minimal reagent consumption, tunable film properties [9] [32]. |

| Inherent Limitations | Time-consuming, uses large volumes of solution, slower diffusion-driven kinetics [9] [32]. | Generally limited to flat substrates; potential for solvent evaporation issues [31]. | Potential for less stable films requiring polyelectrolyte pairing; risk of overspray [32]. |

Detailed Protocols for Core LbL Methods

Protocol: Dip-Assisted LbL Assembly

This traditional LbL method is ideal for substrates of complex geometry and produces highly stable films.

- Materials: Cationic polyelectrolyte (e.g., Polyethyleneimine (PEI)), anionic nanosheets (e.g., Titania Nanosheets (TNS)), substrate (e.g., Thin Film Composite (TFC) membrane), deionized water, pH buffers (if required) [32].

- Procedure:

- Substrate Preparation: Clean the substrate (e.g., a TFC membrane) to remove surface contaminants. For hydrophobic substrates, a plasma treatment may be applied to ensure a uniformly charged, hydrophilic surface.

- Cationic Adsorption: Immerse the substrate in the cationic PEI solution (e.g., 1 mg/mL in deionized water) for a defined period, typically 10-15 minutes, to allow for electrostatic adsorption and charge overcompensation [9] [32].

- Rinsing: Remove the substrate from the PEI solution and rinse it thoroughly with deionized water (e.g., two rinses for 2 minutes each) to remove loosely adsorbed molecules [9] [32].

- Drying: Gently dry the substrate with a stream of inert gas (e.g., Nâ‚‚) or allow it to air-dry.

- Anionic Adsorption: Immerse the substrate into the dispersion of anionic TNS for a similar duration (10-15 minutes) to adsorb the complementary layer [32].

- Rinsing and Drying: Repeat the rinsing and drying steps as in steps 3 and 4.

- Bilayer Repetition: Repeat steps 2-6 until the desired number of bilayers (e.g., 2 bilayers of PEI/TNS [32]) is achieved.

- Post-Assembly Treatment: The final film may be subjected to thermal or chemical cross-linking to enhance its stability, depending on the application.

Protocol: Spin-Assisted LbL (SSLbL) Assembly

This rapid method is highly efficient for coating flat substrates with uniform thin films.

- Materials: Photocatalyst suspension (e.g., Imprinted PDI/PEDOT heterojunction (I-PDI/PEDOT)), solvent (e.g., N-Methyl-2-pyrrolidone (NMP)), porous substrate (e.g., Polyvinylidene Fluoride (PVDF) membrane), spin coater [31].

- Procedure:

- Substrate Preparation: Secure a clean PVDF membrane onto the vacuum chuck of the spin coater.

- Solution Dispensing: Pipette a specific volume (e.g., 1-2 mL) of the I-PDI/PEDOT suspension in NMP onto the center of the stationary membrane. The use of NMP as a solvent for PVDF is strategic, as it induces surface self-corrosion, collapsing pore walls to anchor the photocatalyst firmly [31].

- Spreading Cycle: Initiate a low-speed spin (e.g., 500 rpm for 10 seconds) to spread the solution evenly across the substrate.

- High-Speed Cycle: Immediately ramp to a high rotational speed (e.g., 3000 rpm for 30-60 seconds). This step thins the film, evaporates the solvent, and immobilizes the photocatalyst into the membrane's surface pores via centrifugal force [31].

- Layer Buildup: For multilayer deposition, the process is repeated by dispensing and spinning subsequent layers. The entire assembly of a monolayer can be completed in less than one second in optimized systems [9].

- Membrane Curing: The synthesized photocatalytic membrane (e.g., I-PDI/PEDOT-M) is typically air-dried or lightly heated to ensure stability before use in filtration and degradation experiments [31].

Protocol: Spray-Assisted LbL (SLbL) Assembly

This automated-friendly technique drastically reduces assembly time and reagent consumption.

- Materials: Cationic solution (e.g., PEI), anionic dispersion (e.g., TNS), substrate, spray nozzles (e.g., airbrush), compressed air or nitrogen source, automated spraying system (optional) [32].

- Procedure:

- System Setup: Mount two separate spray nozzles for the cationic and anionic solutions. Adjust the air pressure and solution flow rate for a fine, consistent mist.

- Spraying the First Layer: Direct the spray of the cationic PEI solution uniformly across the substrate surface for a set time (e.g., 5-10 seconds). The spraying action involves bulk movement and random movement followed by electrostatic capture on the substrate [32].

- Drainage and Rinsing: Allow the excess solution to drain off. Spray deionized water over the surface for a few seconds (e.g., 5 seconds) to rinse off excess, loosely bound material [32].

- Drying: Spray a stream of inert gas or air for a few seconds to dry the layer.

- Spraying the Second Layer: Switch to the spray nozzle for the anionic TNS dispersion and repeat the spray-rinse-dry cycle (steps 2-4).

- Bilayer Repetition: Alternate between the cationic and anionic sprays until the desired number of bilayers is achieved. A single bilayer of PEI/TNS can be assembled in minutes [32].

- Post-Assembly Treatment: The spray-assembled film may be annealed or cross-linked to improve its stability, especially upon exposure to electrolyte solutions during filtration [32].

Experimental Workflow and System Relationships

The following diagram illustrates the logical workflow and decision-making process for selecting and implementing the core LbL fabrication methods within a hybrid photocatalyst development pipeline.

LbL Method Selection Workflow

The Scientist's Toolkit: Essential Research Reagents and Materials

The successful implementation of LbL self-assembly relies on a specific set of chemical reagents and materials. This table details the core components of a research toolkit for fabricating hybrid photocatalysts.

Table 2: Essential Research Reagents and Materials for LbL Photocatalyst Fabrication

| Reagent/Material | Typical Function in LbL Assembly | Research Application Context |

|---|---|---|

| Polyethyleneimine (PEI) | Cationic polyelectrolyte; provides positive charge for electrostatic adsorption and improves surface hydrophilicity [32]. | Building block in spray-LbL assembly of PEI/Titania Nanosheet films for antifouling RO membranes [32]. |

| Titania Nanosheets (TNS) | 2D anionic semiconductor nanoparticle; provides high surface area, hydrophilicity, and photocatalytic activity [32]. | Paired with PEI in LbL assembly to create hydrophilic, antifouling coatings on TFC membranes [32]. |

| Perylene Diimide (PDI) | Organic n-type semiconductor; acts as a visible-light-active photocatalyst [31]. | Core component in imprinted PDI/PEDOT heterojunctions for selective tetracycline degradation [31]. |

| Poly-3,4-ethylenedioxythiophene (PEDOT) | Conductive polymer; serves as a functional monomer for molecular imprinting and heterojunction partner [31]. | Used with PDI to form a heterojunction, enhancing charge separation and enabling selective adsorption [31]. |

| N-Methyl-2-pyrrolidone (NMP) | Polar aprotic solvent; induces surface self-corrosion of PVDF substrates to anchor photocatalysts [31]. | Solvent in spin-assisted LbL for immobilizing I-PDI/PEDOT on PVDF membranes without polymer binders [31]. |

| Polyvinylidene Fluoride (PVDF) Membrane | Porous polymeric substrate; provides mechanical support, high permeability, and chemical stability [31]. | Substrate for anchoring photocatalysts via spin-coating, forming a robust photocatalytic membrane [31]. |

| Tetra(4-carboxyphenyl) Porphyrin (TCPP) | Organic macrocyclic compound; acts as a visible-light harvester and photoactive component [28]. | Self-assembled with MoSâ‚‚ nanoflowers via non-covalent interactions to create hybrid photocatalysts for dye degradation [28]. |

| BTD-7 | `BTD-7|TRPC5 Activator|For Research Use` | BTD-7 is a potent TRPC5 channel activator for life science research. This product is For Research Use Only and not for human or veterinary diagnosis or therapeutic use. |

| BTD-2 | BTD-2 | Chemical Reagent |

Application Performance and Data Analysis

The performance of photocatalysts fabricated via different LbL methods can be quantitatively evaluated against key metrics. The following table consolidates experimental data from research findings.

Table 3: Performance Metrics of LbL-Fabricated Photocatalytic Systems

| Photocatalytic System | Fabrication Method | Target Pollutant | Key Performance Metrics | Reference |

|---|---|---|---|---|

| PEI/TNS on TFC Membrane | Spray-Assisted LbL (1 bilayer) | Salt (NaCl) / Organic Foulants | Water Permeability: 1.39 LMH/bar; Salt Rejection: 98.2%; High Fouling Resistance | [32] |

| I-PDI/PEDOT on PVDF (I-PDI/PEDOT-M) | Spin-Assisted LbL (NMP-induced) | Tetracycline (TC) | Selective TC Degradation; Good Water Flux; High Stability & Self-cleaning Ability | [31] |

| MoSâ‚‚/TCPP Hybrid | Self-Assembly (Non-covalent LbL) | Rhodamine B (RhB) | 95.72% Degradation in 75 min under simulated sunlight | [28] |

| AgI/Bi₂Sn₂O₇ Z-Scheme | Hybrid Composites | Tetracycline (TC) | ~83% Degradation in 50 min under visible light | [30] |

The pursuit of efficient and economical catalysts is a central challenge in addressing global energy and environmental crises. Hybrid photocatalytic systems that combine metal oxides and graphitic carbon nitride (g-C₃N₄) have emerged as particularly promising materials. These composites integrate the advantages of both components, often exhibiting enhanced visible-light absorption, improved charge separation efficiency, and superior photocatalytic performance for applications such as hydrogen evolution, CO₂ reduction, and pollutant degradation [33] [34]. The fabrication of these hybrid materials is a critical factor determining their efficacy.

Among various fabrication techniques, the layer-by-layer (LbL) self-assembly method offers a powerful and versatile approach for constructing hybrid thin films with precise control over composition and structure at the nanoscale. This technique is based on the electrostatic interaction between oppositely charged components, allowing for the formation of highly ordered organic-inorganic hybrid architectures [35]. When applied to the construction of metal oxide/g-C₃N₄ composites, the LbL method enables the creation of intimate heterojunctions, which are crucial for facilitating the separation of photogenerated electron-hole pairs and thereby boosting photocatalytic activity [34]. This protocol details the application of LbL self-assembly for fabricating these advanced hybrid photocatalytic systems.

Research Reagent Solutions and Essential Materials

The following table catalogues the key reagents and materials required for the successful fabrication of metal oxide/g-C₃N₄ hybrid systems via LbL self-assembly.

Table 1: Essential Research Reagents and Materials for LbL Fabrication

| Item Name | Function / Role in the Protocol | Specific Example(s) / Notes |

|---|---|---|

| g-C₃N₄ Nanosheets | Primary photocatalyst component; provides a visible-light responsive, polymeric foundation with high chemical stability. | Synthesized via thermal condensation of nitrogen-rich precursors like urea, thiourea, or melamine [34]. |

| Metal Oxide Nanoparticles | Co-catalyst; forms a heterojunction with g-C₃Nâ‚„ to enhance charge separation and provide active sites for redox reactions. | ZnO, TiOâ‚‚, Feâ‚‚O₃, BiOI, or polyoxometalates (POMs) like Naâ‚₆[Znâ‚„(Hâ‚‚O)â‚‚(Pâ‚‚Wâ‚â‚…O₅₆)â‚‚] [34] [36]. |

| Polyelectrolytes | Molecular "glue" for LbL assembly; provides charged sites for electrostatic adsorption of subsequent layers. | Poly(allylamine hydrochloride) (PAH, cationic), Poly(sodium 4-styrenesulfonate) (PSS, anionic), Poly(acrylic acid) (PAA, anionic) [37] [20]. |

| Substrate | Solid support for the deposition of the LbL thin film. | Indium Tin Oxide (ITO)-coated glass, fluorine-doped tin oxide (FTO) glass, or other conductive or porous supports [35]. |

| Background Salt Solutions | Modulates the charge screening and conformation of polyelectrolytes during assembly, influencing film growth and morphology. | Sodium salts (e.g., NaCl, NaNO₃); anion type can be selected from the Hofmeister series (e.g., Fâ», Clâ», NO₃â») to fine-tune the process [37]. |

| Washing Solution | Removes loosely adsorbed molecules or particles between deposition steps, ensuring self-limiting layer growth. | Deionized water or a solvent matching the dispersion medium [35] [20]. |

Detailed Experimental Protocol: LbL Assembly of Hybrid Photocatalytic Films

Preparation of Building Blocks

Synthesis of g-C₃N₄ Nanosheets:

- Place a nitrogen-rich precursor (e.g., 10 g of urea or thiourea) in a covered crucible.

- Heat in a muffle furnace at 550°C for 2–4 hours with a ramp rate of 2–5°C/min to achieve thermal condensation [34].

- Allow the resulting yellow solid to cool to room temperature.

- Grind the bulk g-C₃N₄ into a fine powder. For exfoliation into nanosheets, subject the powder to liquid exfoliation via probe sonication in water or alcohol for several hours [34].

Preparation of Metal Oxide Nanoparticles:

- Synthesize or procure metal oxide nanoparticles (e.g., ZnO, TiOâ‚‚) or anionic metal-oxygen clusters like Polyoxometalates (POMs).

- For POMs, synthesize according to published literature, for example,

Naâ‚₆[Znâ‚„(Hâ‚‚O)â‚‚(Pâ‚‚Wâ‚â‚…O₅₆)â‚‚][35]. - Disperse the nanoparticles in deionized water to form a stable, colloidal suspension (typical concentration: 0.1 - 1 mg/mL) using ultrasonication.

Preparation of Polyelectrolyte Solutions:

- Dissolve the cationic polyelectrolyte (e.g., PAH) and the anionic polyelectrolyte (e.g., PSS or PAA) in deionized water at a concentration of 1-2 mg/mL.

- Adjust the pH of the solutions to optimize the charge density of the weak polyelectrolytes. For instance, a higher pH (>8) deprotonates PAA, enhancing its negative charge, while a lower pH (<6) protonates PAH, enhancing its positive charge [37].

- The addition of a background salt (e.g., 0.1 M NaCl) can be used to screen electrostatic charges and influence the conformation and adsorption kinetics of the polyelectrolytes [37].

Layer-by-Layer Assembly Procedure

The following workflow outlines the sequential deposition process for constructing a hybrid (MO/g-C₃N₄)ₙ thin film, where 'n' represents the number of bilayers.

Detailed Steps:

- Substrate Pretreatment: Clean the substrate (e.g., ITO glass) thoroughly with detergent, deionized water, and ethanol in an ultrasonic bath. Treat the substrate with oxygen plasma or a strong oxidizing agent (e.g., piranha solution) to ensure a clean and uniformly charged surface.

- Adsorption of the First Layer: Immerse the substrate into the cationic solution (this could be a dispersion of protonated g-C₃N₄ nanosheets or a solution of a cationic polyelectrolyte like PAH). A typical immersion time is 10-20 minutes to allow for electrostatic adsorption and monolayer formation [35] [20].